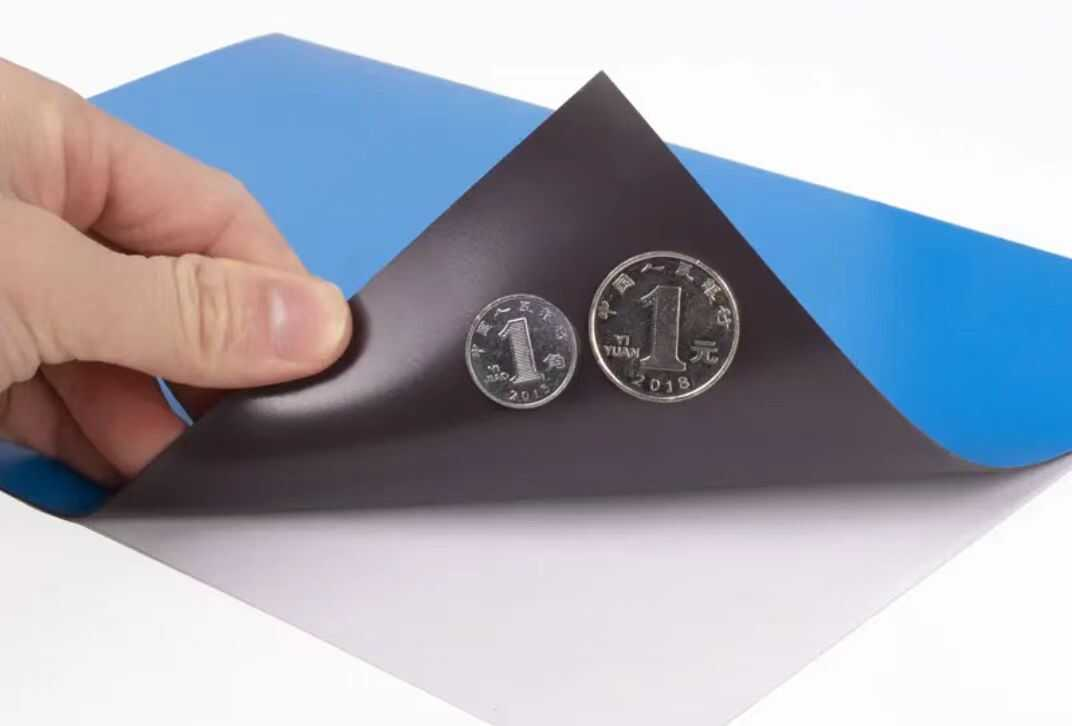

products & Magnetic separators

our magnetic separation equipment. Our fechnological leadership enables us fo meet customer needs more effectively.

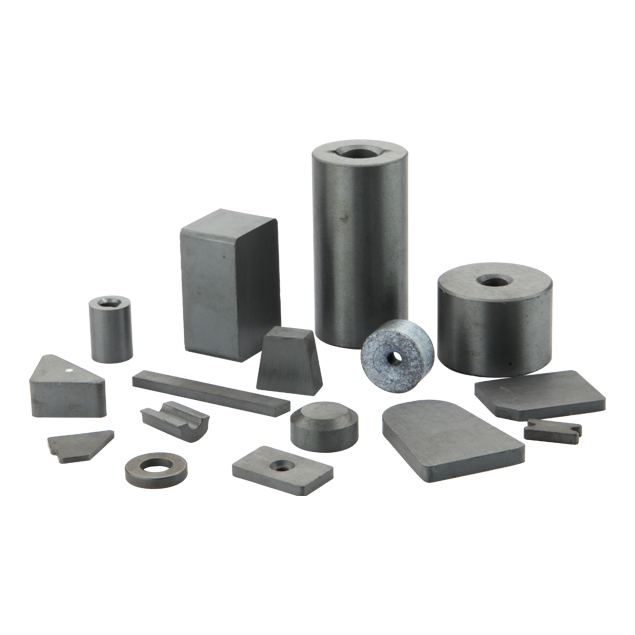

silicon powder industry

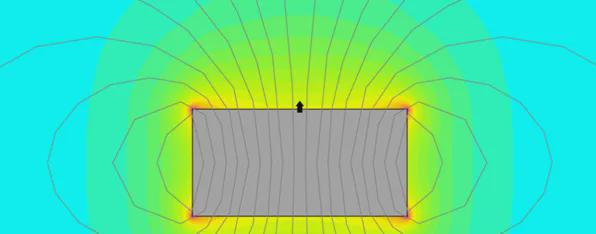

for detecting and separating metal particles in micron-sized materials

for separating iron impurities from ore materials.

Jinhong Machinery: Magnetic Separation Solutions

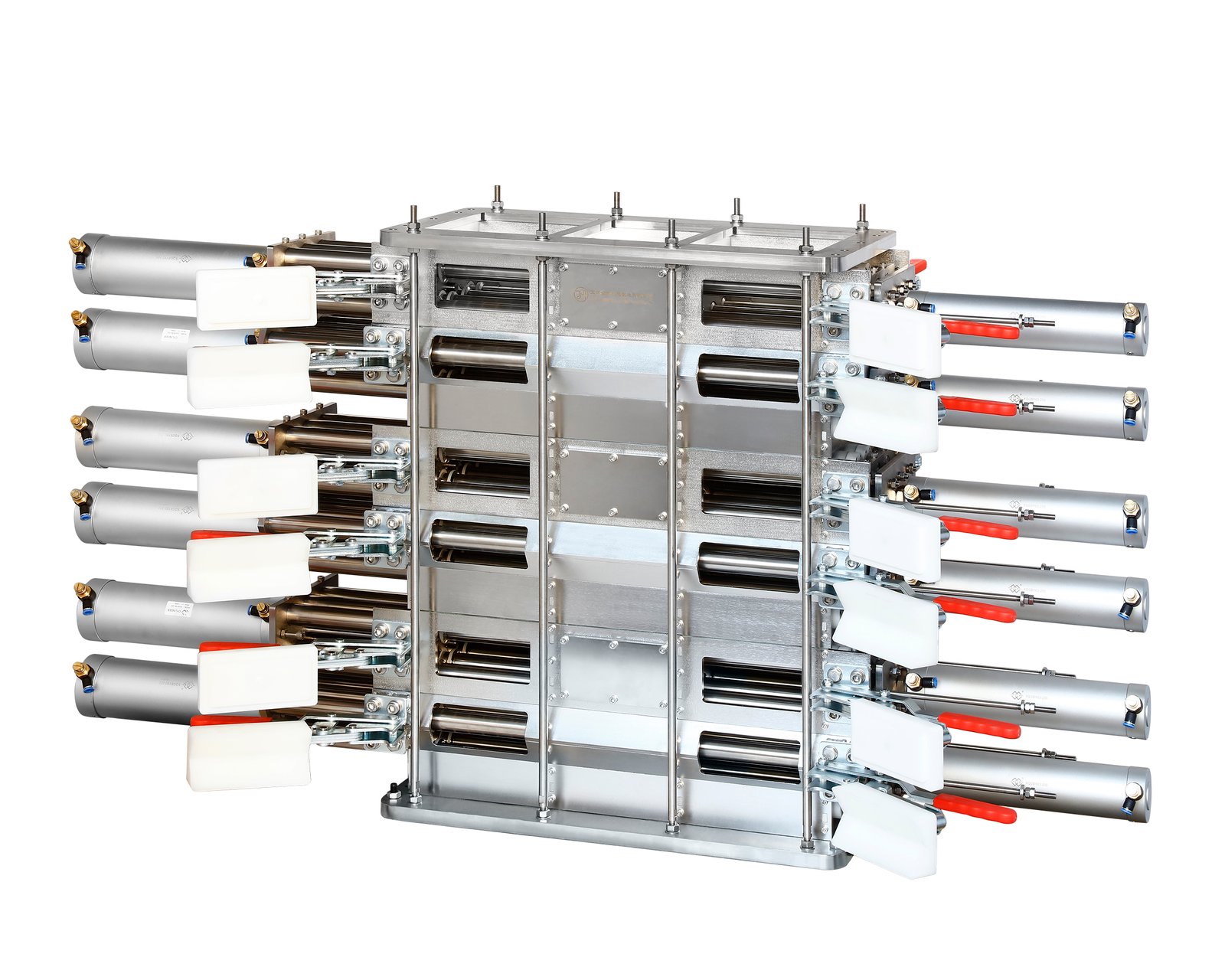

At Jinhong Machinery, we specialize in providing advanced magnetic separation solutions tailored to meet the diverse needs of industries worldwide. With over two decades of expertise, we design and manufacture cutting-edge equipment, including self-cleaning magnetic separators, high-intensity magnetic filters, and grate magnets, to efficiently remove ferrous contaminants from powders, granules, and liquids.

Our solutions are trusted by industries such as food processing, pharmaceuticals, chemicals, mining, and ceramics to enhance product purity, ensure production safety, and optimize operational efficiency. Backed by innovative technology and customer-focused service, Jinhong Machinery is your reliable partner in achieving uncompromising quality and performance.

FEATURES PRODUCTS

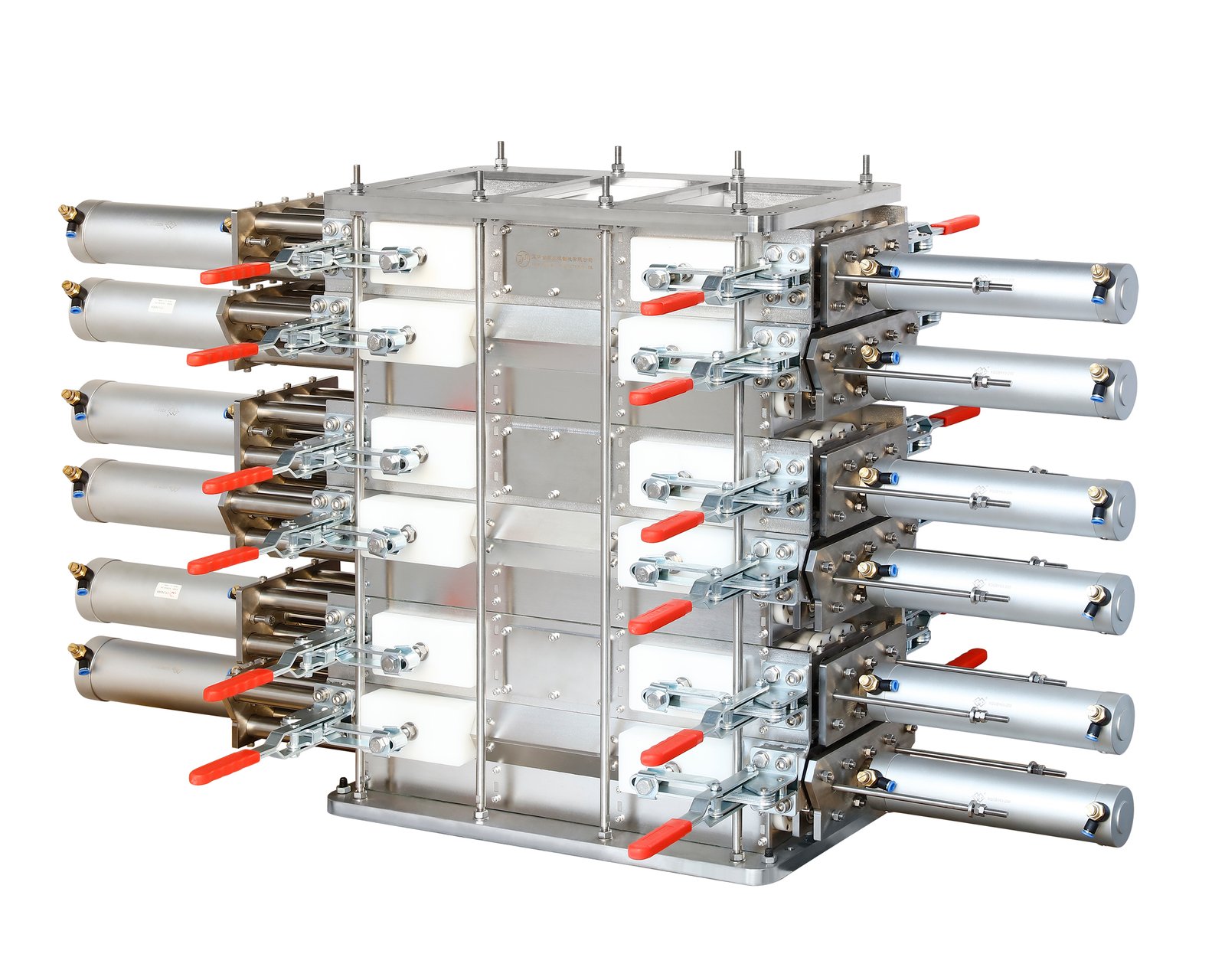

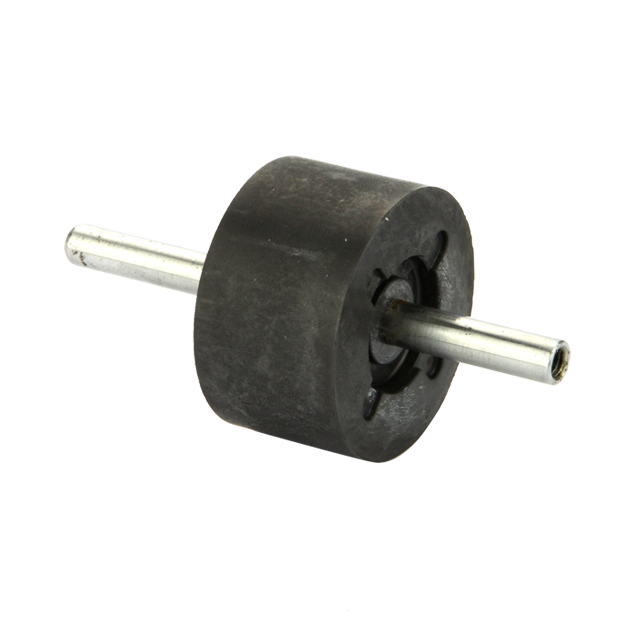

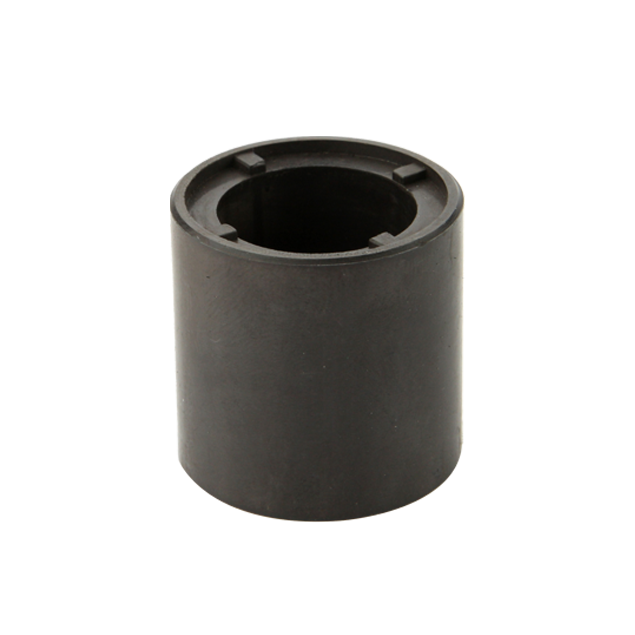

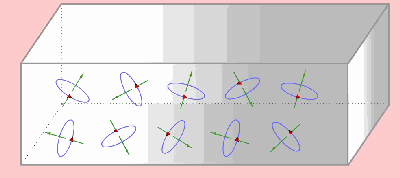

Fluid Pipeline Magnetic Separator

Magnetic Separator Of Self-cleaning Continuous

ABOUT US

Yuhuan Jinhong Machinery Manufacturing Co., Ltd., founded in 2001 and located in Yuhuan, Zhejiang Province, is a professional company that has long provided various functions of iron removal series equipment for domestic and foreign enterprises. This series of equipment can efficiently and economically separate magnetic metal pollutants from powder, granular, and slurry materials, improving the purity and safety of the product. And we can develop comprehensive, comprehensive, and reliable solutions based on the actual process flow of customers. The application fields cover industries such as semiconductors, new energy, pharmaceuticals, food, fine chemicals, pigments, plastics, tobacco, ceramics, mining, glass, etc. We sincerely and efficiently solve production problems for customers.

WHY CHOOSE US

Customized Services

We do custom manufacturing tailored to the customer's needs and offer professional advice on magnetic separation and metal detection.

Independent design and production

We have our own production facilities, R&D personnel, effectively reduce prices and costs, and maintain product quality.

Quality Assurance

We test, measure and certify our own products and third-party products through quality management system ISO 9001:2016 certification.