Alnico Magnets: Overview

Alnico megnets, short for Aluminum-Nickel-Cobalt, is one of the earliest permanent magnetic materials, composed of an alloy of aluminum, nickel, cobalt, iron, and trace elements. It was developed in the 1930s and was once the material of choice for permanent magnets, owing to its superior magnetic properties and low-temperature coefficient. Over time, with the advent of ferrite and rare-earth magnets, Alnico’s role in certain applications has diminished but remains essential in high-temperature and specialized uses.

Introduction

- Composition: Alnico is a ferrous alloy with aluminum (Al), nickel (Ni), cobalt (Co), and sometimes copper (Cu), titanium (Ti), or other elements added for enhanced magnetic properties.

- Properties:

- High coercivity and a Curie temperature exceeding 800°C.

- Produces magnetic fields up to 0.15 Tesla.

- Manufacturing: Due to its brittleness and hardness, Alnico is manufactured through casting or sintering.

A notable Alnico alloy, Alnico-6 (8% Al, 16% Ni, 24% Co, 3% Cu, 1% Ti, balance Fe), has a maximum energy product of 3.9 MG·Oe, coercivity of 780 Oe, and a working temperature up to 525°C.

Types of Alnico Magnets

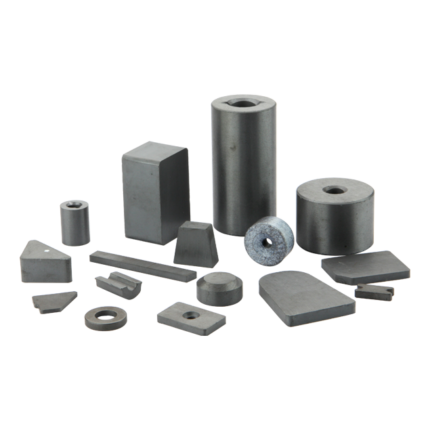

By Manufacturing Method

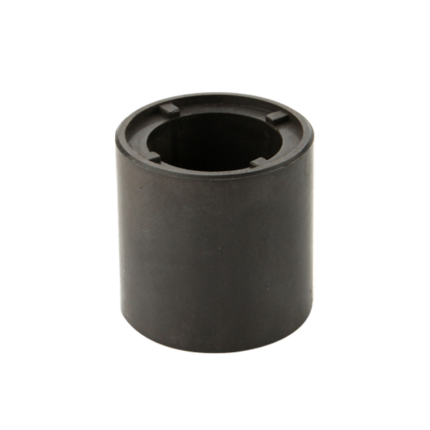

- Cast Alnico:

- Allows production in various shapes and sizes.

- Offers superior magnetic properties.

- Suitable for high-temperature applications.

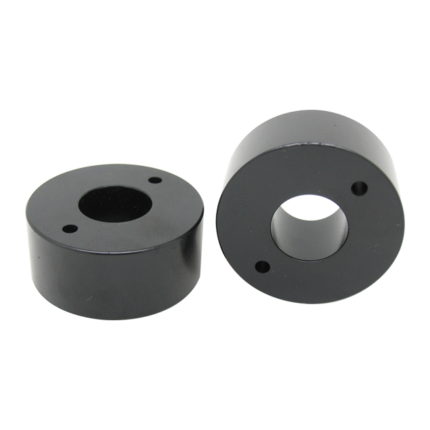

- Sintered Alnico:

- Restricted to smaller dimensions.

- Provides better dimensional tolerances and machinability.

- Magnetic properties are slightly lower than cast Alnico.

By Magnetic Orientation

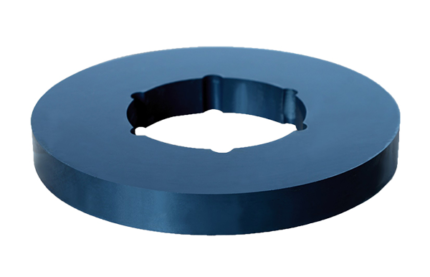

- Isotropic: Equal magnetic properties in all directions.

- Anisotropic: Magnetic properties are optimized along a specific direction.

Performance and Grades

Sintered Alnico Grades

| Material Grade | Max.Energy Prouct

(BH)max |

Remanence

Br |

Intrinsic CoercivityHcj |

Coercivity

Hcb |

Density | Temperature coefficient | Curie Temperature | Remark | ||||

| Kj/cm3 | MGOe | mT | Gs | KA/m | Oe | KA/m | Oe | g/cm3 | %/k | Tc ℃ | ||

| FLN8 | 8-10 | 1.0-1.25 | 520 | 5200 | 43 | 540 | 40 | 500 | 6.7 | -0.0020 | 760 |

Isotropic |

| FLNG12 | 12-14 | 1.5-1.75 | 700 | 7000 | 43 | 540 | 40 | 500 | 7.1 | -0.014 | 810 | |

| FLNGT18 | 14-16 | 1.75-2.0 | 570 | 5700 | 78 | 980 | 76 | 950 | 7.2 | -0.020 | 850 | |

| FLNG28 | 18-22 | 2.25-2.75 | 600 | 6000 | 107 | 1350 | 95 | 1200 | 7.2 | -0.020 | 850 |

Anisotropic |

| FLNG34 | 28-33 | 3.5-4.15 | 1050 | 10500 | 47 | 590 | 46 | 580 | 7.2 | -0.016 | 890 | |

| FLNGT28 | 34-38 | 4.3-4.8 | 1100 | 11000 | 51 | 640 | 50 | 630 | 7.2 | -0.016 | 850 | |

| FLNG38J | 38-40 | 4.75-5.0 | 730 | 7300 | 163 | 2050 | 151 | 1900 | 7.2 | -0.200 | 850 | |

| FLNGT38 | 38-42 | 4.75-5.3 | 800 | 8000 | 126 | 1580 | 123 | 1550 | 7.2 | -0.020 | 850 | |

| FLNGT42 | 42-48 | 5.3-6.0 | 880 | 8800 | 122 | 1530 | 120 | 1500 | 7.25 | -0.020 | 850 | |

Cast Alnico Grades

| Material

Grade |

USA Standard

Equal to MMPA |

Max.Energy Prouct

(BH)max |

Remanence

Br |

Coercivity

Hcb |

Density | Temperature coefficient | Curie Temperature | Remark | |||

| Kj/cm3 | MGOe | mT | Gs | KA/m | Oe | g/cm3 | %/k | Tc ℃ | |||

| LN9 | Alnico1 | 9.0 | 1.13 | 680 | 6800 | 30 | 380 | 6.9 | -0.03 | 760 | Isotropic |

| LN10 | 10.0 | 1.20 | 600 | 6000 | 40 | 500 | 6.9 | 760 | |||

| LNG12 | Alnico2 | 12.4 | 1.55 | 720 | 7200 | 45 | 500 | 7.0 | 810 | ||

| LNG13 | 13.0 | 1.60 | 700 | 7000 | 48 | 600 | 7.0 | 810 | |||

| LNG34 | Alnico5 | 34.0 | 4.30 | 1200 | 12000 | 48 | 600 | 7.3 | -0.02 | 860 | Anisotropic |

| LNG37 | 37.0 | 4.65 | 1200 | 12000 | 48 | 600 | 7.3 | ||||

| LNG40 | Alnico5DG | 40.0 | 5.00 | 1250 | 12500 | 48 | 600 | 7.3 | |||

| LNG44 | 44.0 | 5.50 | 1250 | 12500 | 52 | 650 | 7.3 | ||||

| LNG52 | Alnico5-7 | 52.0 | 6.50 | 1300 | 13000 | 56 | 700 | 7.3 | |||

| LNGT28 | Alnico6 | 28.0 | 3.50 | 1000 | 10000 | 58 | 720 | 7.3 | -0.025 | 860 | |

| LNGT36J | Alnico8H | 36.0 | 4.50 | 700 | 7000 | 140 | 1750 | 7.3 | |||

| LNGT32 | Alnico8 | 32.0 | 4.0 | 800 | 8000 | 100 | 1250 | 7.3 | |||

| LNGT40 | 40.0 | 5.0 | 800 | 8000 | 110 | 1380 | 7.3 | ||||

| LNGT60 | Alnico9 | 60.0 | 7.50 | 900 | 9000 | 110 | 1380 | 7.3 | |||

| LNGT72 | 72.0 | 900 | 1050 | 10500 | 112 | 1400 | 7.3 | ||||

Advantages and Disadvantages

Advantages

- High Residual Induction: Up to 1.35 T, making Alnico magnets highly effective in maintaining a strong magnetic field.

- Excellent Thermal Stability: Low temperature coefficient (-0.02%/°C) and high operating temperatures (up to 600°C).

Disadvantages

- Low Coercivity: Typically below 160 KA/m, leading to vulnerability to demagnetization.

- Non-linear Demagnetization Curve: Requires careful application design.

Applications

Alnico magnets find use in various industries, including:

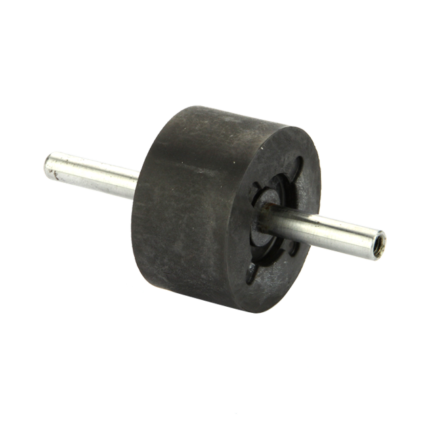

- Electric Motors

- Electric Guitar Pickups

- Microphones

- Sensors and Speakers

- Traveling Wave Tubes (TWTs)

- Cow Magnets: Used in agriculture to attract and capture metallic debris in cows’ stomachs.

While Alnico magnets have been largely replaced by rare-earth magnets for many applications, their unique properties make them irreplaceable in high-temperature and specific low-demagnetization settings.