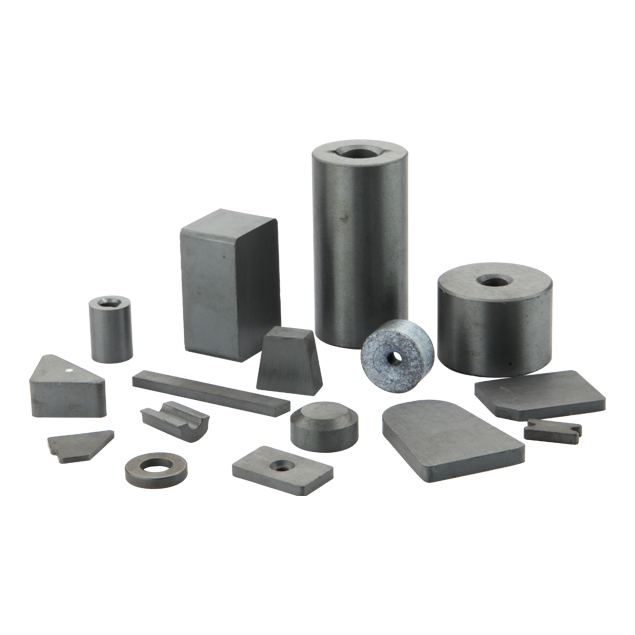

Sintered Ferrite Magnets: An Overview

Sintered ferrite magnets is primarily composed of BaFe₁₂O₁₉ and SrFe₁₂O₁₉. Based on the orientation of their magnetic crystals, sintered ferrites can be classified into isotropic and anisotropic magnets. Due to their low cost and moderate magnetic properties, they are among the most widely used magnets.

Manufactured through the powder metallurgy process, their chemical composition is Ba/Sr 0.6 Fe₂O₃.

Sintered Ferrite Magnets Production and Properties

- Annual Production: Over 300,000 tons.

- Manufacturing Process: Using ceramic technology, which results in a hard yet brittle material.

- Key Features:

- Excellent temperature resistance.

- Low cost, making them the most commonly used permanent magnets.

- Chemical Composition: Ba/Sr 0.6 Fe₂O₃.

Physical Properties

- Curie Temperature: 450°C

- Maximum Operating Temperature: 250°C

- Hardness: 480–580 Hv

- Density: 4.8–4.9 g/cm³

Magnetic Performance

Sintered ferrite magnets are available in two types:

- Isotropic Magnets: Lower magnetic performance. (e.g., Y10)

- Anisotropic Magnets: Higher performance grades such as Y25, Y30, Y35, and Y30BH.

Performance Table for Sintered Permanent Ferrite Magnets:

Sintered Ferrite Magnets Grades

| Grade | Residual Induction (Br) | Coercivity (HcB) | Intrinsic Coercivity (HcJ) | Max Energy Product (BH)max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| Y8T | 200~235 | 2.0~2.35 | 125-160 | 1.57-2.01 | 210-280 | 2.64-3.51 | 6.5-9.5 | 0.8-1.2 |

| Y22H | 310~360 | 3.10~3.60 | 220-250 | 2.76-3.14 | 280-320 | 3.51-4.02 | 20.0-24.0 | 2.5-3.0 |

| Y25 | 360~400 | 3.60~4.00 | 135-170 | 1.70-2.14 | 140-200 | 1.76-2.51 | 22.5-28.0 | 2.8-3.5 |

| Y26H-1 | 360~390 | 3.60~3.90 | 200-250 | 2.51-3.14 | 225-255 | 2.83-3.20 | 23.0-28.0 | 2.9-3.5 |

| Y26H-2 | 360~380 | 3.60~3.80 | 263-288 | 3.30-3.62 | 318-350 | 3.99-4.40 | 24.0-28.0 | 3.0-3.5 |

| Y27H | 350~380 | 3.50~3.80 | 225-240 | 2.83-3.01 | 235-260 | 2.95-3.27 | 25.0-29.0 | 3.1-3.6 |

| Y28 | 370~400 | 3.70~4.00 | 175-210 | 2.20-3.64 | 180-220 | 2.26-2.76 | 26.0-30.0 | 3.3-3.8 |

| Y28H-1 | 380~400 | 3.80~4.00 | 240-260 | 3.01-3.27 | 250-280 | 3.14-3.52 | 27.0-30.0 | 3.4-3.8 |

| Y28H-2 | 360~380 | 3.60~3.80 | 271-295 | 3.40-3.70 | 382-405 | 4.80-5.08 | 26.0-30.0 | 3.3-3.8 |

| Y30H-1 | 380~400 | 3.80~4.00 | 230-275 | 2.89-3.46 | 235-290 | 2.95-3.64 | 27.0-32.5 | 3.4-4.1 |

| Y30H-2 | 395~415 | 3.95~4.15 | 275-300 | 3.45-3.77 | 310-335 | 3.89-4.20 | 27.0-32.0 | 3.4-4.0 |

| Y32 | 400~420 | 4.00~4.20 | 160-190 | 2.01-2.39 | 165-195 | 2.07-2.45 | 30.0-33.5 | 3.8-4.2 |

| Y32H-1 | 400~420 | 4.00~4.20 | 190-230 | 2.39-2.89 | 230-250 | 2.89-3.14 | 31.5-35.0 | 3.9-4.4 |

| Y32H-2 | 400~440 | 4.00~4.40 | 224-240 | 2.81-3.01 | 230-250 | 2.89-3.14 | 31.0-34.0 | 3.9-4.3 |

| Y33 | 410~430 | 4.10~4.30 | 220-250 | 2.76-3.14 | 225-255 | 2.83-3.20 | 31.5-35.0 | 3.9-4.4 |

| Y33H | 410~430 | 4.10~4.30 | 250-270 | 3.14-3.39 | 250-275 | 3.14-3.45 | 31.5-35.0 | 3.9-4.4 |

| Y34 | 420~440 | 4.20~4.40 | 200-230 | 2.51-2.89 | 205-235 | 2.57-2.95 | 32.5-36.0 | 4.1-4.4 |

| Y35 | 430~450 | 4.30~4.50 | 215-239 | 2.70-3.00 | 217-241 | 2.73-3.03 | 33.1-38.2 | 4.1-4.8 |

| Y36 | 430~450 | 4.30~4.50 | 247-271 | 3.10-3.40 | 250-274 | 3.14-3.44 | 35.1-38.3 | 4.4-4.8 |

| Y38 | 440~460 | 4.40~4.60 | 285-305 | 3.58-3.83 | 294-310 | 3.69-3.89 | 36.6-40.6 | 4.6-5.1 |

| Y40 | 440~460 | 4.40~4.60 | 330-354 | 4.15-4.45 | 340-360 | 4.27-4.52 | 37.6-41.8 | 4.7-5.2 |

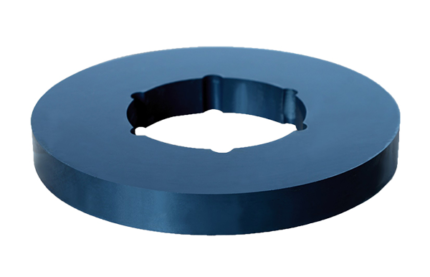

Applications

Sintered ferrite magnets are widely used in various industries, including:

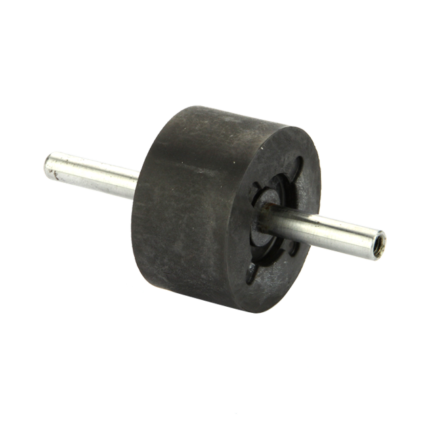

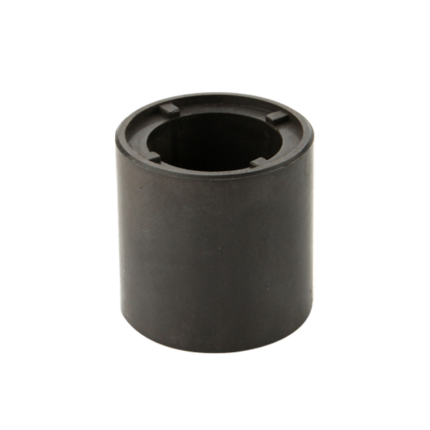

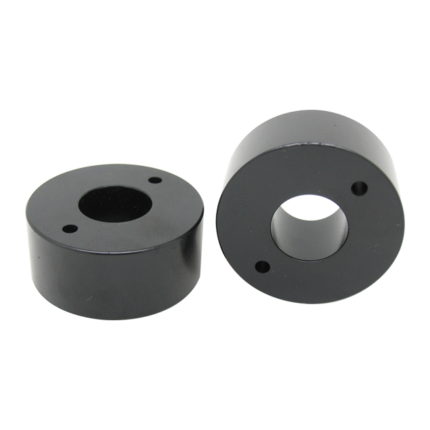

- Motors:

- Permanent magnet synchronous motors (PMSMs).

- Stepper motors.

- DC motors.

- Electrical Devices:

- Loudspeakers.

- Power supplies.

- Automotive Industry:

- Electric vehicles (EVs).

- Hybrid electric vehicles (HEVs).

- Machinery:

- Magnetic chucks.

- Magnetic tools.

Precautions for Use

- Brittleness: Sintered ferrite magnets are fragile and prone to damage from impact, vibration, and friction.

- Avoid Overloading: Over-saturation, prolonged overcurrent, or exposure to high temperatures can degrade magnetic performance.

- Magnetic Decay: Magnetic properties may weaken over time; regular inspection and replacement are necessary.

Sintered Ferrite Magnets Conclusion

Sintered ferrite magnets are widely used magnetic materials with numerous advantages, including cost-effectiveness and temperature resistance. Proper manufacturing processes and usage precautions are essential to ensure their stability and longevity.