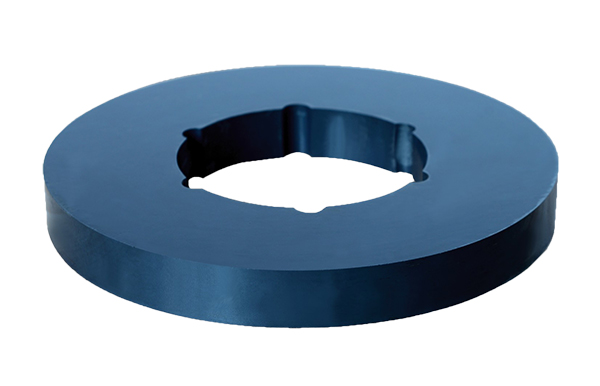

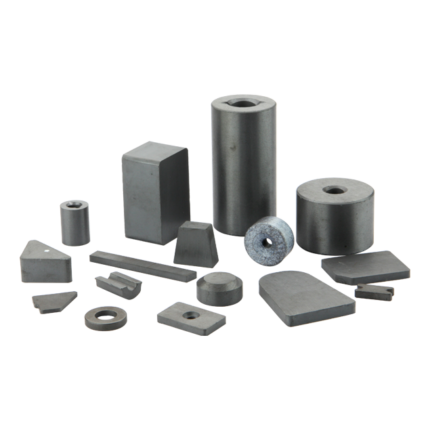

Ferrite Magnets

Ferrite magnets are a type of permanent magnet primarily manufactured using SrO (strontium oxide) or BaO (barium oxide) and Fe₂O₃ (iron oxide) as raw materials. Compared to other permanent magnets, ferrite magnets are hard and brittle, with relatively low magnetic energy. However, they are resistant to demagnetization and corrosion, feature a simple production process, and are cost-effective. These properties make ferrite magnets the most widely produced and applied magnets in industrial production.

Ferrite Magnets Material Overview

Ferrite magnets belong to the category of sintered permanent magnetic materials, composed of barium or strontium ferrite. They are notable for:

- High resistance to demagnetization, maintaining stable magnetic properties.

- Low cost, due to abundant raw materials and simple production methods.

- Brittle and hard nature, requiring special machining techniques.

Magnetic Orientation

- Anisotropic magnets: Stronger magnetic properties but can only be magnetized along a specific orientation.

- Isotropic magnets: Weaker magnetic properties but can be magnetized in any direction.

Magnetic energy ranges from 1.1 MGOe to 4.0 MGOe. Ferrite materials can be categorized into various types such as soft magnetic, hard magnetic (including bonded magnets), gyromagnetic, Torque and piezomagnetic materials and other specialized materials.

Ferrite Magnets Key Features:

- Soft magnetic materials: High permeability, low coercivity, and low loss.

- Hard magnetic materials: High coercivity (Hc) and high magnetic energy product (BH)max.

- Gyromagnetic materials: Exhibit gyromagnetic properties for microwave communication devices.

- Torque and piezomagnetic materials: High linear magnetostrictive coefficient, suitable for specific industrial uses.

Material Characteristics

- Production Method: Powder metallurgy.

- Magnetic Properties: Low residual magnetism, low magnetic permeability, high coercivity.

- Corrosion Resistance: Made mainly of oxides, offering strong corrosion resistance.

- Operating Temperature: From -40°C to +200°C.

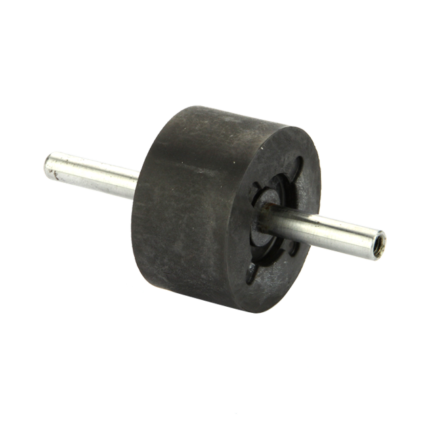

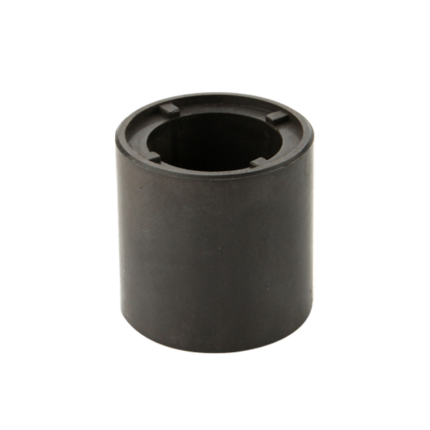

- Applications: Widely used in motors, speakers, toys, and crafts.

Performance Specifications

Sintered Ferrite Magnets Grades

| Grade | Residual Induction (Br) | Coercivity (HcB) | Intrinsic Coercivity (HcJ) | Max Energy Product (BH)max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| Y8T | 200~235 | 2.0~2.35 | 125-160 | 1.57-2.01 | 210-280 | 2.64-3.51 | 6.5-9.5 | 0.8-1.2 |

| Y22H | 310~360 | 3.10~3.60 | 220-250 | 2.76-3.14 | 280-320 | 3.51-4.02 | 20.0-24.0 | 2.5-3.0 |

| Y25 | 360~400 | 3.60~4.00 | 135-170 | 1.70-2.14 | 140-200 | 1.76-2.51 | 22.5-28.0 | 2.8-3.5 |

| Y26H-1 | 360~390 | 3.60~3.90 | 200-250 | 2.51-3.14 | 225-255 | 2.83-3.20 | 23.0-28.0 | 2.9-3.5 |

| Y26H-2 | 360~380 | 3.60~3.80 | 263-288 | 3.30-3.62 | 318-350 | 3.99-4.40 | 24.0-28.0 | 3.0-3.5 |

| Y27H | 350~380 | 3.50~3.80 | 225-240 | 2.83-3.01 | 235-260 | 2.95-3.27 | 25.0-29.0 | 3.1-3.6 |

| Y28 | 370~400 | 3.70~4.00 | 175-210 | 2.20-3.64 | 180-220 | 2.26-2.76 | 26.0-30.0 | 3.3-3.8 |

| Y28H-1 | 380~400 | 3.80~4.00 | 240-260 | 3.01-3.27 | 250-280 | 3.14-3.52 | 27.0-30.0 | 3.4-3.8 |

| Y28H-2 | 360~380 | 3.60~3.80 | 271-295 | 3.40-3.70 | 382-405 | 4.80-5.08 | 26.0-30.0 | 3.3-3.8 |

| Y30H-1 | 380~400 | 3.80~4.00 | 230-275 | 2.89-3.46 | 235-290 | 2.95-3.64 | 27.0-32.5 | 3.4-4.1 |

| Y30H-2 | 395~415 | 3.95~4.15 | 275-300 | 3.45-3.77 | 310-335 | 3.89-4.20 | 27.0-32.0 | 3.4-4.0 |

| Y32 | 400~420 | 4.00~4.20 | 160-190 | 2.01-2.39 | 165-195 | 2.07-2.45 | 30.0-33.5 | 3.8-4.2 |

| Y32H-1 | 400~420 | 4.00~4.20 | 190-230 | 2.39-2.89 | 230-250 | 2.89-3.14 | 31.5-35.0 | 3.9-4.4 |

| Y32H-2 | 400~440 | 4.00~4.40 | 224-240 | 2.81-3.01 | 230-250 | 2.89-3.14 | 31.0-34.0 | 3.9-4.3 |

| Y33 | 410~430 | 4.10~4.30 | 220-250 | 2.76-3.14 | 225-255 | 2.83-3.20 | 31.5-35.0 | 3.9-4.4 |

| Y33H | 410~430 | 4.10~4.30 | 250-270 | 3.14-3.39 | 250-275 | 3.14-3.45 | 31.5-35.0 | 3.9-4.4 |

| Y34 | 420~440 | 4.20~4.40 | 200-230 | 2.51-2.89 | 205-235 | 2.57-2.95 | 32.5-36.0 | 4.1-4.4 |

| Y35 | 430~450 | 4.30~4.50 | 215-239 | 2.70-3.00 | 217-241 | 2.73-3.03 | 33.1-38.2 | 4.1-4.8 |

| Y36 | 430~450 | 4.30~4.50 | 247-271 | 3.10-3.40 | 250-274 | 3.14-3.44 | 35.1-38.3 | 4.4-4.8 |

| Y38 | 440~460 | 4.40~4.60 | 285-305 | 3.58-3.83 | 294-310 | 3.69-3.89 | 36.6-40.6 | 4.6-5.1 |

| Y40 | 440~460 | 4.40~4.60 | 330-354 | 4.15-4.45 | 340-360 | 4.27-4.52 | 37.6-41.8 | 4.7-5.2 |

Bonded Ferrite Magnets Grades

| Grade | Residual Induction (Br) | Coercivity (HcB) | Intrinsic Coercivity (HcJ) | Max Energy Product (BH)max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| YN1T | 63-83 | 0.63-0.83 | 50-70 | 0.63-0.88 | 175-210 | 2.20-2.64 | 0.8-1.2 | 0.1-0.15 |

| YN4H | 135-155 | 1.35-1.55 | 85-105 | 1.07-1.32 | 175-210 | 2.20-2.64 | 3.2-4.5 | 0.4-0.56 |

| YN4TH | 150-180 | 1.50-1.80 | 95-120 | 1.19-1.38 | 180-230 | 2.26-2.89 | 3.8-5.5 | 0.48-0.69 |

| YN6T | 180-220 | 1.80-2.20 | 120-140 | 1.28-1.76 | 175-200 | 2.20-2.51 | 5.0-7.0 | 0.63-0.88 |

| YN10 | 220-240 | 2.20-2.40 | 145-165 | 1.82-2.07 | 190-225 | 2.39-2.83 | 9.2-10.6 | 1.15-1.33 |

| YN10H | 220-250 | 2.20-2.50 | 150-200 | 1.88-2.51 | 190-220 | 2.39-2.76 | 9.2-11.0 | 1.15-1.38 |

| YN11 | 230-250 | 2.30-2.50 | 160-185 | 2.01-2.32 | 225-260 | 2.83-3.27 | 10.0-12.0 | 1.25-1.5 |

| YN12 | 240-250 | 2.40-2.50 | 140-160 | 1.76-2.01 | 200-230 | 2.51-2.89 | 11.4-13.6 | 1.43-1.7 |

Comparison with Neodymium Magnets

| Property | Ferrite Magnets | Neodymium Magnets |

|---|---|---|

| Material Type | Composite of ferromagnetic oxides | Rare-earth alloy |

| Magnetic Strength | Low (800-1000 Gauss) | High (approx. 3500 Gauss) |

| Corrosion Resistance | Excellent, no surface treatment required | Poor, requires protective coating |

| Thermal Stability | High, suitable for higher temperatures | Lower, susceptible to thermal degradation |

| Cost | Economical, low production cost | Higher cost, better performance-to-price ratio |

| Applications | Motors, speakers, toys, crafts | Electronics, precision devices, aerospace |

Conclusion

Ferrite magnets are highly valued for their cost-effectiveness, stability, and wide range of industrial applications. While their magnetic performance is not as strong as neodymium magnets, their resistance to demagnetization and corrosion ensures their continued significance in the magnet industry.