Pneumatic Magnetic Separator Of JH-LX Series Continuous Main Features :

-

Installation Locations:

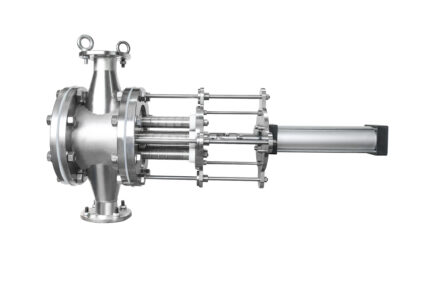

- Magnetic separator Suitable for installation in circular and square pipes for gravity free-fall applications.

- Common installation locations include:

- Downstream of vibrating screens, rotary valves, feeding stations, and feeding mechanisms.

- Upstream of crushers, packaging machines, and other required positions.

- Designed for continuous 24/7 operation.

-

Automatic Iron Filings Cleaning:

- This equipment automatically removes iron filings during operation.

- To ensure timely collection of cleaned iron filings and dust, a dust collector with a wind pressure of >2000Pa and a flow rate of >400m³/h is required.

-

Compressed Air Power:

- Powered by compressed air with a pressure of <0.5MPa and a dew point of -20℃. If used in electronic products, the compressed air must be oil-free and purified to prevent contamination.

- Operates with PLC control and a touchscreen input automatic control system for easy operation.

-

Magnetic Field Strength and Temperature Range:

- The maximum surface magnetic field strength for the standard series is 12,000-13,000 GS.

- The working temperature for standard models is ≤80℃.

- For higher temperature environments, strong magnetic materials can be used, with a maximum working temperature of 250℃.

-

Customizable Magnetic Core Types:

- The device can be adapted to different materials by using different magnetic cores:

- JH-B type standard cylindrical magnetic core.

- JH-L type spiral magnetic field cylindrical core.

- These magnetic cores are designed to optimize cost performance and maximize the iron removal effect.

- The device can be adapted to different materials by using different magnetic cores:

-

Iron Powder Removal Effectiveness:

- The equipment is designed to effectively remove iron particles larger than 100 microns (about 150 mesh), based on test results.

Specifications of JH-LX Series Magnetic Separator:

-

JH-04B:

- Equipped with 2 sets of standard continuous pneumatic iron removal units.

- Each unit has 4 layers and 16 sets of iron removal combinations.

- Total of 8 layers and 32 sets, powered by 4 pairs of cylinder groups.

- Overall Dimensions: 1766mm × 360mm × 768mm.

-

JH-06B:

- Equipped with 3 sets of standard continuous pneumatic iron removal units.

- Each unit has 4 layers and 16 sets of iron removal combinations.

- Total of 12 layers and 48 sets, powered by 6 pairs of cylinder groups.

- Overall Dimensions: 1766mm × 360mm × 1008mm.

-

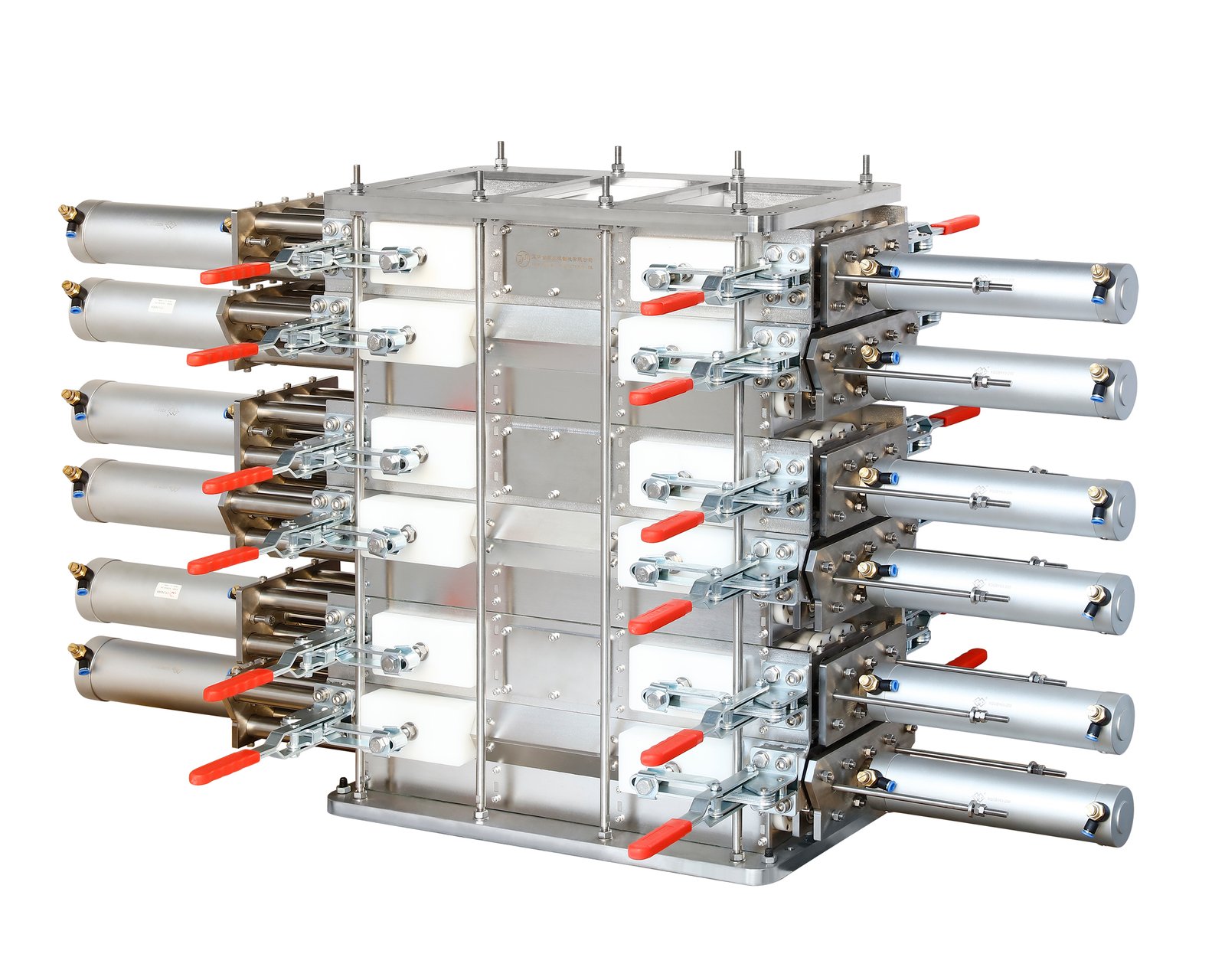

JH-12B:

- Equipped with 6 sets of standard continuous pneumatic iron removal units.

- Each unit has 4 layers and 16 sets of iron removal combinations.

- Total of 24 layers and 96 sets, powered by 12 pairs of cylinder groups.

- Overall Dimensions: 1766mm × 360mm × 1722mm.

-

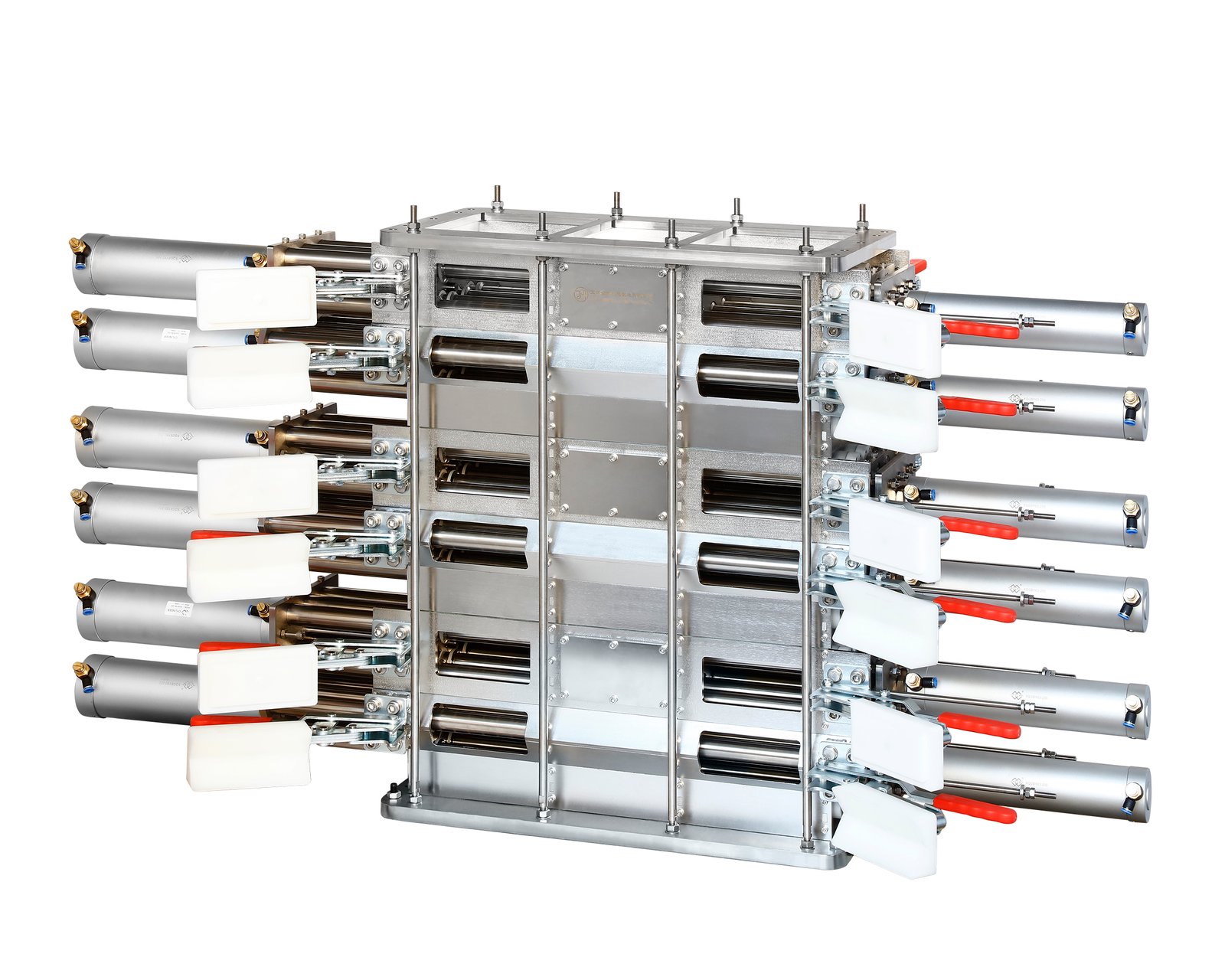

JH-06X:

- Specialized for ultra-fine powder applications.

- Equipped with 3 sets of dedicated continuous pneumatic iron removal units.

- Each unit has 9 sets of iron removal combinations on two levels.

- Total of 27 sets on 6 levels, driven by 6 pairs of cylinder groups.

- Overall Dimensions: 1842mm × 360mm × 1008mm.

Note: The above dimensional parameters are for reference only. For exact measurements, please refer to the factory inspection report or order contract.

Customization:

- Non-standard designs can be tailored according to specific user requirements, allowing for adaptation to various material characteristics and operational needs.

Applications:

- Food Processing: Effectively removes metal contaminants from powders, grains, and other raw materials to ensure product purity.

- Chemical Industry: Used to prevent iron contamination in sensitive chemical production processes.

- Plastic and Rubber Industry: Ensures iron removal from plastic pellets or rubber materials.

- Pharmaceuticals: Removes iron contaminants from raw materials used in drug manufacturing to comply with strict quality standards.

Magnetic Separator Benefits:

- High-Efficiency Iron Removal: With a magnetic field strength up to 13,000 GS, the unit ensures effective iron removal from various materials.

- Cost-Effective: The equipment offers high performance with optimized cost efficiency due to the customizable magnetic cores and flexible design options.

- Reliable and Durable: Designed for 24-hour continuous operation with minimal maintenance, ideal for industries requiring consistent iron removal over long periods.

- Flexible Design: Adaptable for a wide range of materials and specific operational conditions, with options for high and low-temperature environments.

The JH-LX series continuous pneumatic magnetic separator is an excellent solution for industries looking to improve product quality by efficiently removing iron contaminants from bulk materials, while ensuring low operational costs and easy maintenance.