Neodymium Magnets Overview

Neodymium magnets, also known as NdFeB magnets, are composed of neodymium (Nd), iron (Fe), and boron (B) in a tetragonal crystalline structure. Renowned for their exceptional strength, they are one of the most widely used rare-earth magnets.

Applications and Characteristics of NdFeB Magnets

Applications

1. Electronics:

- Found in hard drives, mobile phones, headphones, and battery-powered tools.

- Provide high energy density and excellent magnetic performance, making them essential in modern industrial and electronic technologies.

2. Other Industries:

- Machinery

- Hardware

- Toys

- Packaging

- Medical devices

- Aerospace

Their versatility makes them indispensable for applications requiring compact and powerful magnets.

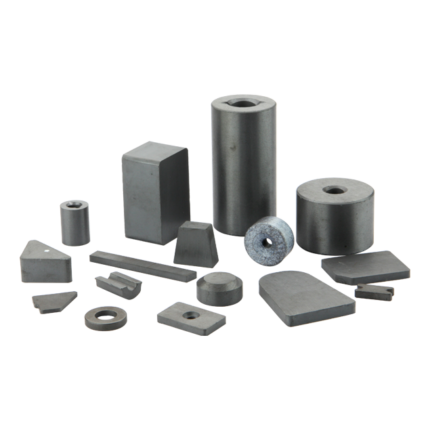

Types of NdFeB Magnets

1. Sintered NdFeB Magnets:

- Require surface coatings (e.g., nickel, zinc, epoxy) to prevent corrosion.

2. Bonded NdFeB Magnets:

- Exhibit magnetic properties in all directions.

- Naturally resistant to corrosion.

These traits make NdFeB magnets ideal for applications demanding strong magnetic forces. However, their brittleness necessitates careful handling during use to avoid damage.

Product Guidelines: Safe Usage of Magnetized Products

Precautions for Use

- Keep magnetized products away from sensitive items such as floppy disks, magnetic cards, cassette tapes, credit cards, electronic devices, digital dashboards, pacemakers, and other medical equipment.

Handling Safety

- Due to their strong magnetic force, handle them with care to avoid finger injuries.

Material Durability

- NdFeB (Neodymium Iron Boron) and SmCo (Samarium Cobalt) magnets have low impact resistance. Take extra care during transportation and handling to prevent damage or breakage.

These guidelines ensure the safe and efficient use of magnetized products while safeguarding users and surrounding equipment.

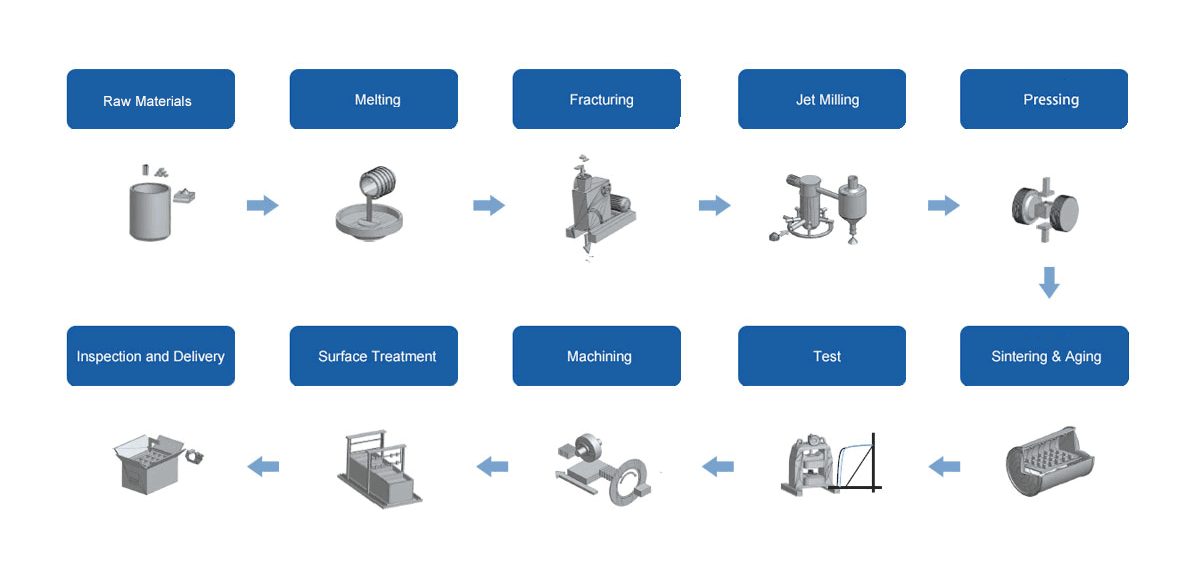

Process Flow:

Grade Curve:

Magnetic Performance Table:

| Grade | Remanence(Br) | Coercivity(Hcb) | Intrinsic Coercivity Force(Hcj) | Max.Energy Product(BH)m | Working Temp | ||||||||

| kGs | T | KOe | KA/m | KOe | KA/m | MGOe | KJ/m3 | ℃ | |||||

| Nom. | min. | Nom. | min. | min. | min. | Nom. | min. | Nom. | min. | ||||

| N35 | 12.3 | 11.8 | 1.23 | 1.18 | 10.8 | 860 | ≥12 | ≥955 | 36 | 33 | 287 | 263 | ≤80 |

| N38 | 12.8 | 12.3 | 1.28 | 1.23 | 10.8 | 860 | ≥12 | ≥955 | 39 | 36 | 310 | 287 | ≤80 |

| N40 | 13.1 | 12.6 | 1.31 | 1.26 | 10.8 | 860 | ≥12 | ≥955 | 41 | 38 | 326 | 302 | ≤80 |

| N42 | 13.4 | 12.9 | 1.34 | 1.29 | 10.8 | 860 | ≥12 | ≥955 | 43 | 40 | 342 | 318 | ≤80 |

| N45 | 13.8 | 13.3 | 1.38 | 1.33 | 10.8 | 860 | ≥12 | ≥955 | 46 | 43 | 366 | 342 | ≤80 |

| N48 | 14.2 | 13.7 | 1.42 | 1.37 | 10.8 | 860 | ≥12 | ≥955 | 49 | 45 | 390 | 358 | ≤80 |

| N50 | 14.4 | 13.9 | 1.44 | 1.39 | 10.8 | 860 | ≥12 | ≥955 | 51 | 47 | 406 | 370 | ≤80 |

| N52 | 14.7 | 14.2 | 1.47 | 1.42 | 10.5 | 836 | ≥12 | ≥955 | 53 | 49 | 422 | 390 | ≤80 |

| N54 | 15.0 | 14.5 | 1.50 | 1.45 | 10.5 | 836 | ≥12 | ≥955 | 55 | 51 | 438 | 406 | ≤80 |

| N55 | 15.2 | 14.7 | 1.52 | 1.47 | 10.5 | 836 | ≥12 | ≥955 | 56 | 52 | 446 | 414 | ≤60 |

| N56 | 15.2 | 14.8 | 1.52 | 1.58 | 10.5 | 836 | ≥12 | ≥955 | 56 | 52 | 446 | 414 | ≤60 |

| 38M | 12.8 | 12.3 | 1.28 | 1.23 | 11 | 876 | ≥14 | ≥1114 | 35 | 33 | 279 | 263 | ≤100 |

| 40M | 13.1 | 12.6 | 1.31 | 1.26 | 11.4 | 910 | ≥14 | ≥1114 | 38 | 36 | 303 | 287 | ≤100 |

| 42M | 13.4 | 12.9 | 1.34 | 1.29 | 11.8 | 938 | ≥14 | ≥1114 | 40 | 38 | 318 | 303 | ≤100 |

| 45M | 13.8 | 13.3 | 1.38 | 1.33 | 12.2 | 971 | ≥14 | ≥1114 | 42 | 40 | 334 | 318 | ≤100 |

| 48M | 14.2 | 13.7 | 1.42 | 1.37 | 12.7 | 1012 | ≥14 | ≥1114 | 45 | 43 | 358 | 342 | ≤100 |

| 50M | 14.4 | 13.9 | 1.44 | 1.39 | 13.1 | 1043 | ≥14 | ≥1114 | 48 | 46 | 383 | 367 | ≤100 |

| 52M | 14.7 | 14.2 | 1.47 | 1.42 | 13.1 | 1043 | ≥14 | ≥1114 | |||||

| 54M | 14.9 | 14.4 | 1.49 | 1.44 | 13.1 | 1043 | ≥14 | ≥1114 | |||||

| 56M | 15.0 | 14.6 | 1.50 | 1.46 | 13.1 | 1043 | ≥14 | ≥1114 | |||||

| N33H | 11.7 | 11.4 | 1.17 | 1.14 | 10.3 | 820 | ≥17 | ≥1353 | 33 | 31 | 263 | 247 | ≤120 |

| N35H | 12.1 | 11.7 | 1.21 | 1.17 | 10.8 | 860 | ≥17 | ≥1353 | 35 | 33 | 279 | 263 | ≤120 |

| N38H | 12.6 | 12.2 | 1.26 | 1.22 | 11.5 | 915 | ≥17 | ≥1353 | 38 | 36 | 303 | 287 | ≤120 |

| N40H | 12.9 | 12.6 | 1.29 | 1.26 | 11.5 | 915 | ≥17 | ≥1353 | 40 | 38 | 318 | 303 | ≤120 |

| N42H | 13.2 | 12.9 | 1.32 | 1.29 | 12.2 | 971 | ≥17 | ≥1353 | 42 | 40 | 334 | 318 | ≤120 |

| N45H | 13.6 | 13.2 | 1.36 | 1.32 | 12.4 | 987 | ≥17 | ≥1353 | 45 | 43 | 358 | 342 | ≤120 |

| N48H | 13.8 | 13.6 | 1.38 | 1.36 | 12.4 | 987 | ≥17 | ≥1353 | 47 | 45 | 375 | 358 | ≤120 |

| N30SH | 11.2 | 10.8 | 1.12 | 1.08 | 9.8 | 780 | ≥20 | ≥1595 | 30 | 28 | 239 | 223 | ≤150 |

| N33SH | 11.7 | 11.4 | 1.17 | 1.14 | 10.3 | 820 | ≥20 | ≥1595 | 33 | 31 | 263 | 247 | ≤150 |

| N35SH | 12.1 | 11.7 | 1.21 | 1.17 | 10.8 | 860 | ≥20 | ≥1595 | 35 | 33 | 279 | 263 | ≤150 |

| N38SH | 12.6 | 12.2 | 1.26 | 1.22 | 11.8 | 939 | ≥20 | ≥1595 | 38 | 36 | 303 | 287 | ≤150 |

| N40SH | 12.9 | 12.6 | 1.29 | 1.26 | 12 | 955 | ≥20 | ≥1595 | 40 | 38 | 318 | 303 | ≤150 |

| N42SH | 13.2 | 12.8 | 1.32 | 1.28 | 12.2 | 971 | ≥20 | ≥1595 | 42 | 40 | 334 | 318 | ≤150 |

| N45SH | 13.5 | 13.3 | 1.35 | 1.33 | 12.2 | 981 | ≥20 | ≥1595 | 45 | 42 | 358 | 334 | ≤150 |

| N28UH | 10.8 | 10.4 | 1.08 | 1.04 | 9.8 | 780 | ≥25 | ≥1990 | 28 | 26 | 223 | 207 | ≤180 |

| N30UH | 11.2 | 10.8 | 1.12 | 1.08 | 10.1 | 804 | ≥25 | ≥1990 | 30 | 28 | 239 | 223 | ≤180 |

| N33UH | 11.7 | 11.4 | 1.17 | 1.14 | 10.3 | 820 | ≥25 | ≥1990 | 33 | 31 | 263 | 247 | ≤180 |

| N35UH | 12.1 | 11.7 | 1.21 | 1.17 | 10.8 | 860 | ≥25 | ≥1990 | 35 | 33 | 279 | 263 | ≤180 |

| N38UH | 12.4 | 12.1 | 1.24 | 1.21 | 11.4 | 908 | ≥25 | ≥1990 | 38 | 35 | 303 | 279 | ≤180 |

| N40UH | 12.7 | 12.4 | 1.27 | 1.24 | 11 | 924 | ≥25 | ≥1990 | 40 | 38 | 318 | 303 | ≤180 |

| N42UH | 13 | 12.8 | 1.3 | 1.28 | 12 | 955 | ≥25 | ≥1990 | 42 | 40 | 342 | 318 | ≤180 |

| N28EH | 10.8 | 10.4 | 1.08 | 1.04 | 9.8 | 780 | ≥30 | ≥2388 | 28 | 26 | 223 | 207 | ≤200 |

| N30EH | 11.2 | 10.8 | 1.12 | 1.08 | 10.1 | 804 | ≥30 | ≥2388 | 30 | 28 | 239 | 223 | ≤200 |

| N33EH | 11.7 | 11.2 | 1.17 | 1.12 | 10.4 | 828 | ≥30 | ≥2388 | 33 | 30 | 263 | 239 | ≤200 |

| N35EH | 12.1 | 11.7 | 1.21 | 1.17 | 10.8 | 860 | ≥30 | ≥2388 | 36 | 33 | 287 | 263 | ≤200 |

| N38EH | 12.4 | 12 | 1.24 | 1.2 | 11.6 | 924 | ≥30 | ≥2388 | 38 | 35 | 303 | 287 | ≤200 |

| N28AH | 10.8 | 10.4 | 1.08 | 1.04 | 10 | 796 | ≥33 | ≥2626 | 28 | 26 | 223 | 207 | ≤240 |

| N30AH | 11.2 | 10.8 | 1.12 | 1.08 | 10.1 | 804 | ≥33 | ≥2626 | 30 | 28 | 239 | 223 | ≤240 |

| N33AH | 11.7 | 11.2 | 1.17 | 1.12 | 10.4 | 828 | ≥33 | ≥2626 | 33 | 31 | 263 | 247 | ≤240 |

| N35AH | 12.1 | 11.7 | 1.21 | 1.17 | 10.8 | 860 | ≥33 | ≥2626 | 35 | 33 | 279 | 263 | ≤240 |