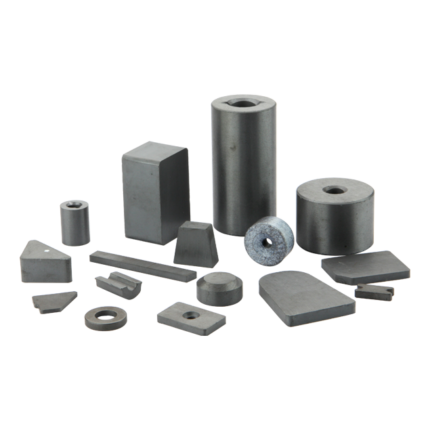

Samarium Cobalt Magnet Main Applications

Samarium Cobalt magnet, known for their high magnetic energy product, coercivity, and resistance to high temperatures, are widely utilized across numerous industries. Below are their primary applications:

1. Aerospace

- Used in the manufacturing of high-performance permanent magnet motors and sensors to ensure stability in extreme altitudes and temperatures.

2. Defense and Military

- Essential in the production of precision navigation systems and weaponry due to their excellent magnetic properties and corrosion resistance.

3. Microwave Devices and Communications

- Employed in the creation of magnetic components for microwave devices and communication equipment, ensuring stable performance at high frequencies.

4. Medical Equipment

- Integrated into MRI machines and other precision medical devices, serving as crucial components.

5. Instruments and Gauges

- Utilized in the development of various high-precision instruments, ensuring consistent operation in diverse environments.

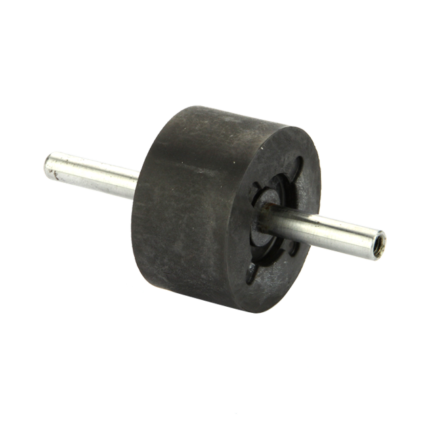

6. Magnetic Transmission Devices and Sensors

- Widely applied in industrial automation and control systems, such as magnetic transmission devices and sensors.

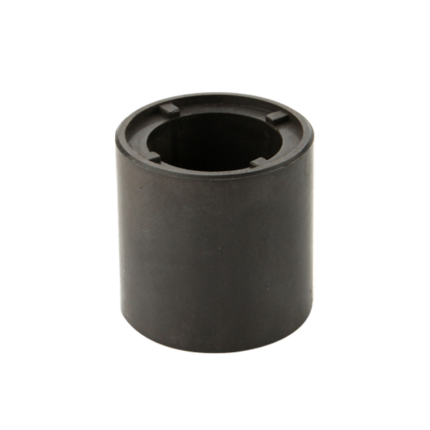

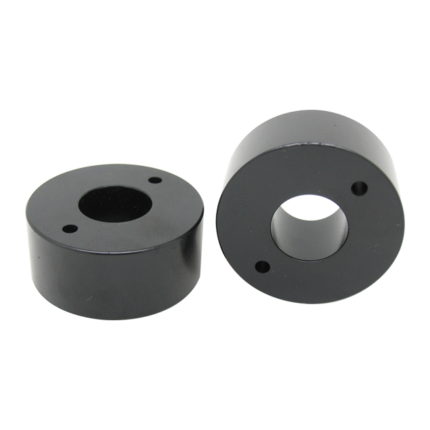

7. Motors and Magnetic Lifters

- Favored in the production of high-performance motors and magnetic lifting devices due to their temperature resistance and strong magnetism.

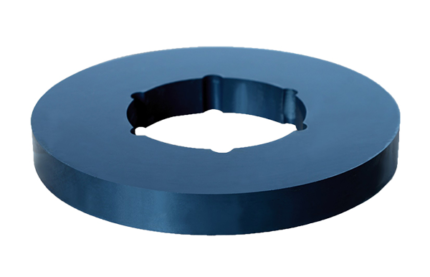

Physical and Chemical Properties of SmCo Magnets

1. High Magnetic Energy Product

- Maximum magnetic energy product ranges between 160-150 KJ/m³ (15-35 MGoe).

2. High Coercivity

- Intrinsic coercivity exceeds 1194 kA/m (15 kOe).

- Magnetic induction coercivity ranges from 650-870 kA/m (4-12 kOe).

3. Temperature Resistance

- Maximum operating temperature reaches 250-350°C, making them suitable for high-temperature applications.

4. Strong Corrosion Resistance

- Exceptional resistance to corrosion and oxidation, typically eliminating the need for surface coatings.

5. Low Temperature Coefficient

- Above 180°C, SmCo magnets exhibit better stability in maximum magnetic energy product, coercivity, and temperature performance compared to NdFeB magnets.

SmCo magnets’ robust magnetic properties, resistance to harsh environments, and thermal stability make them indispensable in high-performance and demanding applications.

Precautions for Handling Magnetized Products

- Avoid Sensitive Items:

Magnetized products should be kept away from items such as:- Floppy disks

- Magnetic cards and tapes

- Credit cards

- Electronic devices and dashboards

- Medical devices like pacemakers or similar equipment

- Safety While Handling:

- Magnetized steel has a strong magnetic force, so exercise caution during use to prevent finger injuries from pinching.

- Impact Sensitivity:

- NdFeB (Neodymium) and SmCo (Samarium Cobalt) magnets are brittle and sensitive to impact.

- Ensure care is taken during transportation, handling, and use to avoid damage or chipping, especially at the edges.

By adhering to these precautions, you can ensure safe handling and prolonged functionality of magnetized products.

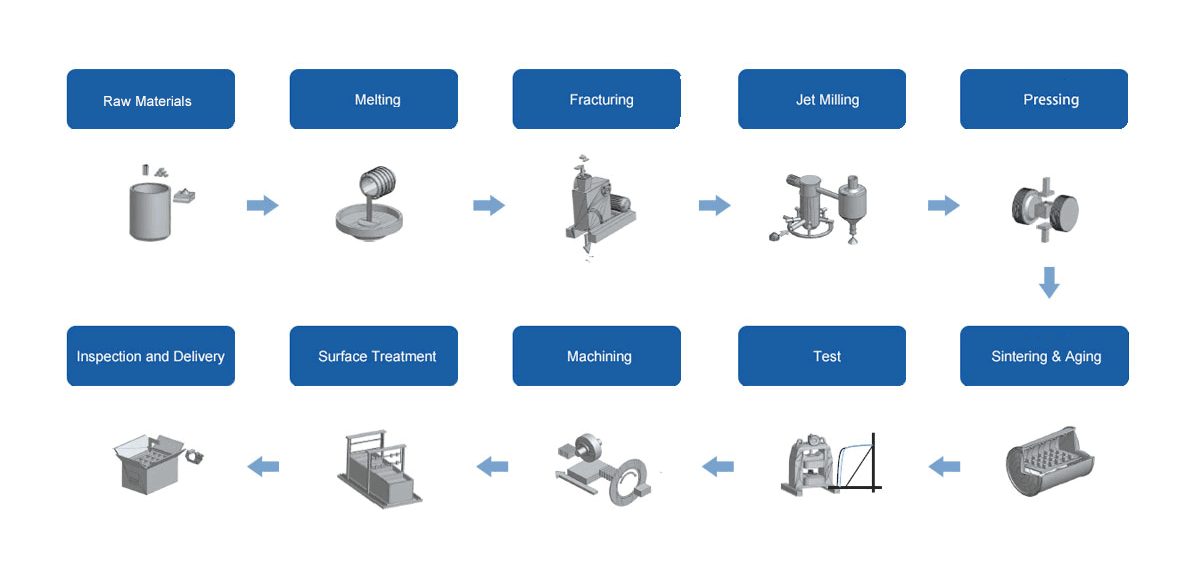

Process Flow:

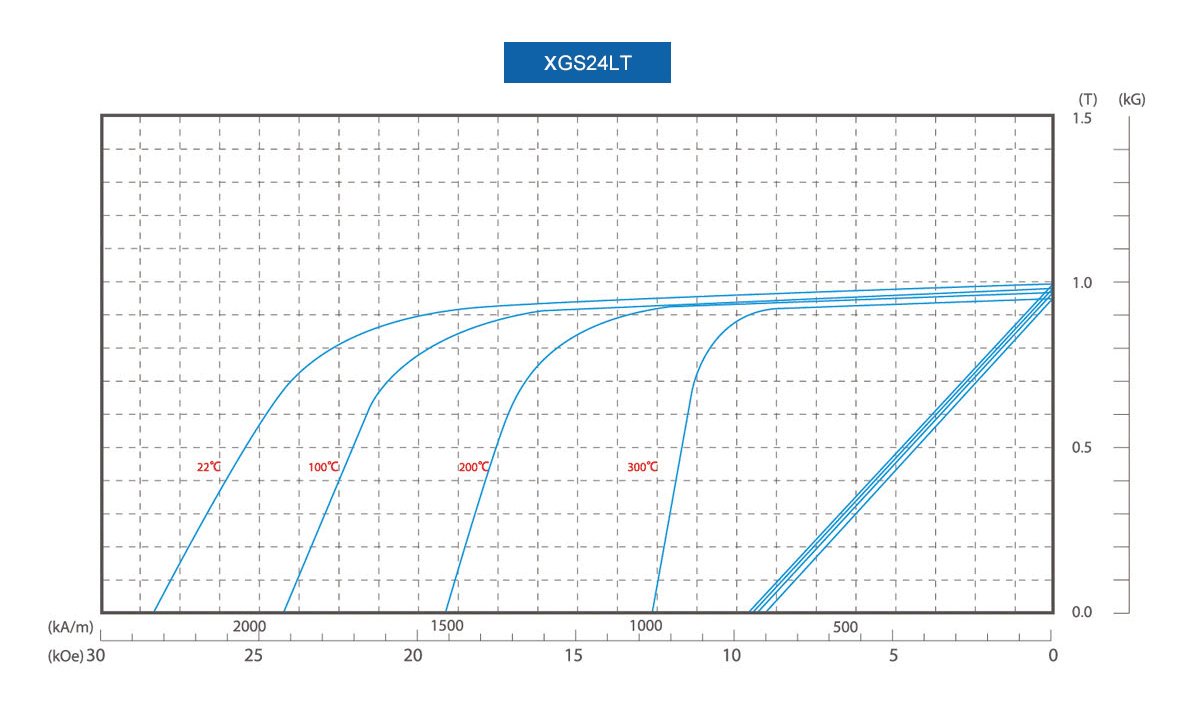

Grade Curve:

Standard Specification: