Rotary Magnetic Separator

The Rotary Magnetic Separator is an advanced solution for removing ferrous contaminants from various materials in processing pipelines. Its innovative design ensures optimal efficiency, high precision, and ease of operation across multiple industries.

Main Features

1. Rotating Magnetic Rod with Isolation Sheath

- Prevents Clogging: The rotating magnetic rod design eliminates material bridging, ensuring smooth flow through the pipeline.

- Effortless Cleaning: Cleaning is simplified without causing secondary contamination in the housing or conveying pipes.

- Enhanced Purity: The isolation sheath prevents removed contaminants from re-entering the material stream, maintaining high product quality.

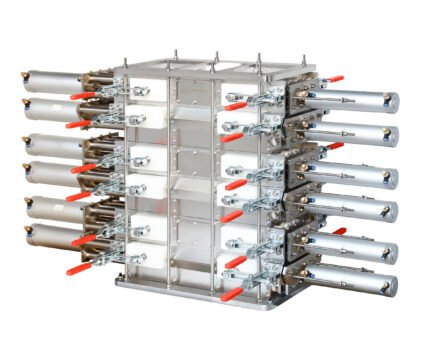

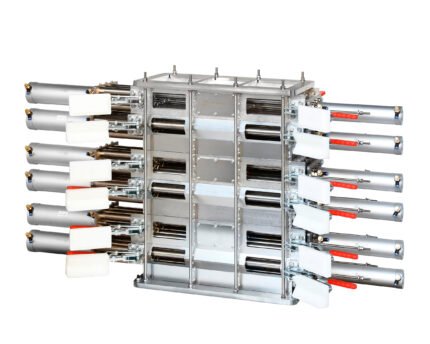

2. Adaptable Magnetic Rod Types

- The system offers three customizable rod types to suit different material characteristics:

- JH-B Type: Standard cylindrical rods.

- JH-L Type: Spiral magnetic field rods.

- JH-Z Type: Linear magnetic field rods.

- Each rod type features optimized magnetic field designs for superior iron removal efficiency.

3. High Magnetic Field Strength

- Up to 15,000 GS: Ensures effective separation of even the smallest iron particles.

- Temperature Range: Standard operation at ≤80℃; special models available for temperatures up to 350℃ to handle high-temperature materials.

4. Quick-Opening Structure

- Easy Maintenance: Features a quick-opening lid with a reliable seal for fast access during cleaning or maintenance.

- Hygienic Cleaning: The isolation sheath can be easily removed to prevent contamination during cleaning.

5. Adjustable Rotation Speed

- Frequency Conversion Control: Allows rotation speed to be tailored to match the material flow rate, optimizing separation efficiency.

- Scalability: Multiple rotating iron removers can be connected in series for high-precision applications.

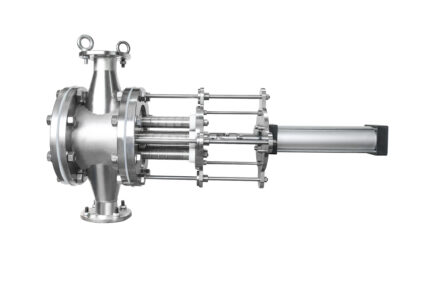

6. Flexible Interface Design

- Offers round or square flange interfaces at the inlet and outlet.

- Compatible with horizontal and vertical pipeline installations, enabling versatile integration.

Rotary Magnetic Separator Benefits

- Efficient Iron Removal:

- High magnetic field strength ensures the capture of ferrous particles, including those smaller than 100 microns.

- Customizable for Versatility:

- Adaptable configurations to suit various materials and operational conditions.

- Easy to Maintain:

- The quick-opening structure and removable sheath simplify cleaning and reduce downtime.

- Adjustable for Consistency:

- Fine-tuning of rotation speed ensures consistent performance with varying material flow rates.

Applications

This system is ideal for removing iron contaminants from powders, liquids, and bulk materials in the following industries:

- Food Processing: Ensures purity of raw materials like flour, spices, and grains.

- Pharmaceutical Manufacturing: Removes iron particles to maintain hygiene and product quality.

- Chemical Production: Handles powders and liquids while maintaining strict quality standards.

- Plastic Recycling: Eliminates ferrous particles from pellets or plastic materials.

- Mining and Mineral Processing: Separates ferrous contaminants from ores and minerals.

Specialized Use Cases:

- High-precision applications requiring the removal of ultra-fine contaminants.

- Processing of high-temperature materials with special models designed for temperatures up to 350℃.

The Rotating Magnetic Rod Iron Remover delivers reliable, high-performance iron removal, making it an essential tool for industries requiring consistent quality, safety, and operational efficiency.

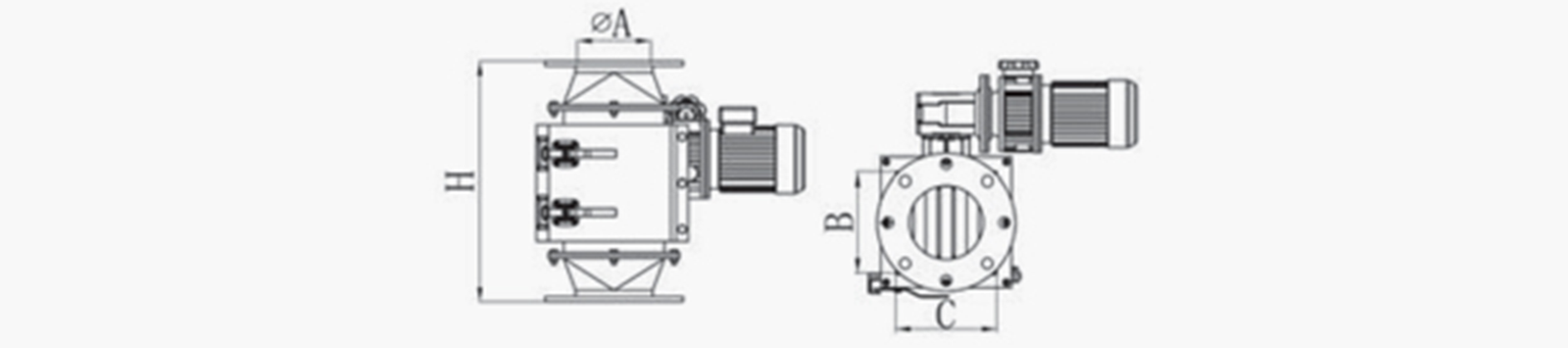

Equipment Parameters:

| Model | ∅A | B | C | H | Power | Magnetic Rod Quantity |

| JH-W06 | 150 | 205 | 208 | 450 | 0.25 | 7 |

| JH-W08 | 200 | 255 | 258 | 500 | 0.25 | 9 |

| JH-W10 | 250 | 305 | 308 | 550 | 0.25 | 11 |

| JH-W12 | 300 | 355 | 358 | 600 | 0.37 | 13 |

| JH-W14 | 350 | 405 | 408 | 650 | 0.37 | 15 |