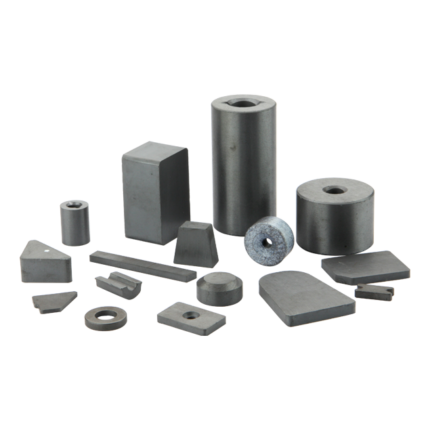

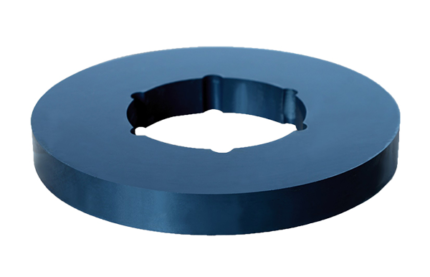

Injection Molded Ferrite Magnets: An Overview

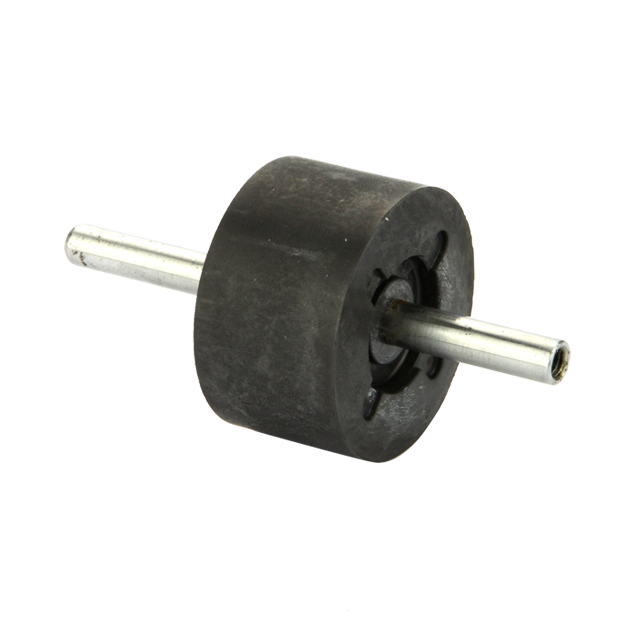

Injection molded ferrite magnets are manufactured by mixing ferrite magnetic powder with resin materials such as PA6, PA12, PA66, or PPS. The mixture is then shaped through injection molding. These magnets are widely used in automation equipment, permanent magnet DC motors, axial fans, inverter air conditioner motors, and instrument motors. They are indispensable signal sources and constant magnetic sources for precision micro-motors and the automation industry, offering unique advantages unmatched by other types of magnets.

Injection Molded Ferrite Magnets Product Features

- Magnetization Options:

- Axial unipolar magnetization.

- Radial multipolar magnetization.

- Combined axial and radial magnetization.

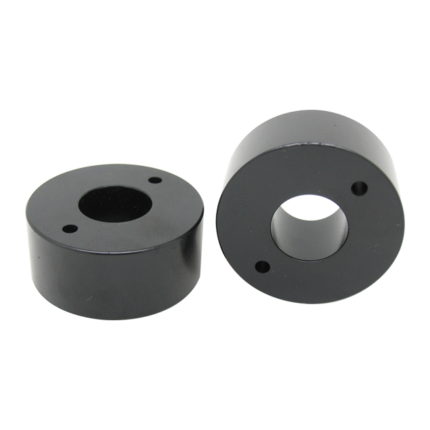

- High Precision:

- Smooth and flawless surface appearance.

- High dimensional accuracy and consistency, eliminating the need for post-processing.

- Stable and Durable:

- Excellent performance stability.

- Resistance to vibration and impact.

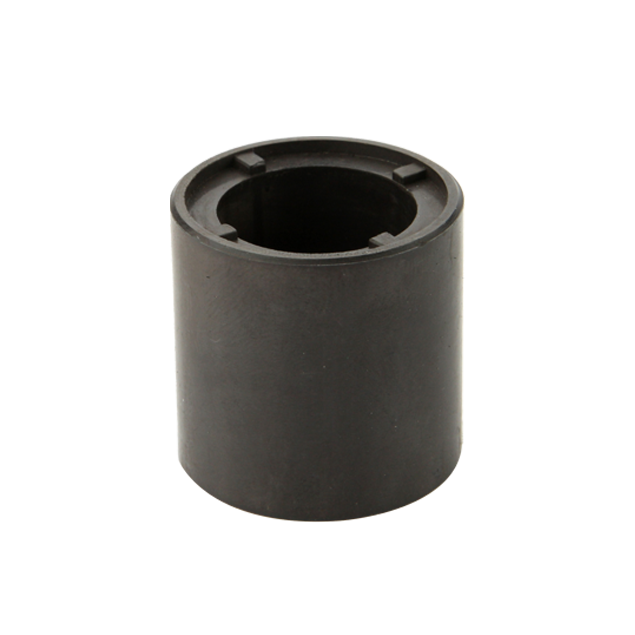

- Complex Design Capability:

- Can be manufactured into intricate shapes, making them suitable for precision applications.

These features make injection magnets an irreplaceable choice in the precision micro-motor and automation industries.

Applications

Injection magnets find applications in the following areas:

- Automation Equipment:

- Essential in automated machinery and systems.

- Permanent Magnet DC Motors:

- Widely used in various motor-driven applications.

- Axial Fans:

- Used in cooling and ventilation systems.

- Inverter Air Conditioner Motors:

- Key components in energy-efficient air conditioning systems.

- Instrument Motors:

- Critical for precision instrumentation and measurement devices.

Injection magnets combine precision, durability, and versatility, making them indispensable in modern industrial and technological applications. Their adaptability to complex designs and stable performance ensures their continued importance in a wide range of industries.