Magnetic Separation & Filtration Solutions in the Pharmaceutical and Food Industries

Magnetic separation and filtration solutions are crucial in the pharmaceutical and food industries. Jinhong Machinery provides efficient magnetic separation technology that effectively removes metal contaminants introduced during production, ensuring the purity and safety of the final products. These solutions not only protect equipment from damage but also prevent health risks and costly product recalls caused by metal impurities. Whether in pharmaceutical manufacturing or food processing, our magnetic filtration systems help businesses improve production efficiency, meet strict quality standards, safeguard consumer safety, and maintain brand reputation.

Applied in Pharmaceutical Industry: Removing Metal Impurities in Pharmaceuticals

Throughout various stages of pharmaceutical manufacturing, tiny metal particles, including weakly magnetic stainless steel fragments, can inadvertently mix into the product. These particles can range in particle size, often requiring larger magnetic fields to ensure effective removal. High-strength magnets, utilizing high magnetic field gradients and magnetic moments, are needed to capture these particles. The introduction of these contaminants into pharmaceutical products can compromise their purity and safety, potentially causing severe consequences, including health risks to patients, regulatory issues, and financial losses due to product recalls. Magnetic separator design plays a key role in creating effective systems to address these challenges.

Magnetic filters and separators are used to capture these unwanted metal particles, preventing contamination and ensuring that the products meet the strict quality standards required in the pharmaceutical industry. These filtration solutions, often designed for high throughput, are particularly important in protecting sensitive manufacturing equipment from damage and maintaining the integrity of the final products.

Applications in Food Processing

Similarly, in the food industry, magnetic filtration technology plays a crucial role in maintaining food safety and quality. Metal contaminants, even in very small quantities, can pose serious health risks to consumers and damage the reputation of food manufacturers. Magnetic separators are used at various stages of food production to remove any ferrous and non-ferrous metal particles, such as those from packaging materials, machinery, or raw materials. Coated magnetic materials, with specific magnetic properties, are used to enhance the effectiveness of these filtration systems, especially in food products that require special handling due to their production process.

By effectively removing these contaminants, magnetic filtration systems help to prevent foreign material contamination, ensure compliance with food safety regulations, and uphold the reputation of food brands in the market.

Magnetic filtration solutions are critical in both the pharmaceutical and food industries for maintaining product quality and safety. In the pharmaceutical industry, they help prevent contamination from metal particles, which could lead to health risks and costly recalls. In the food industry, they help ensure that food products are free from harmful metal contaminants, safeguarding both consumers and manufacturers. The continuous advancement in magnetic separation technology, including high gradient magnetic separation HGMS, ensures these industries meet stringent standards and provide safer, high-quality products.

Metal Contamination Issues

In liquid, emulsion, and other solution-based products (such as solutions, emulsions, suspensions, etc., which may result from blending or compression processes), metal contamination is a significant concern. During the mixing process of various liquids and other substances, manufacturers often rely on equipment such as pumps, grinders, stirrers, and homogenizers. The operation of these machines can release very fine steel or stainless steel particles, which can eventually mix into the liquid. Additionally, during equipment cleaning and maintenance, loose metal parts (such as machine components) may accidentally fall into the product flow. Given the rapid development and stringent standards in the pharmaceutical industry, manufacturers urgently need efficient magnetic separation equipment to thoroughly remove iron-based contaminants from products like milk powder and pharmaceuticals.

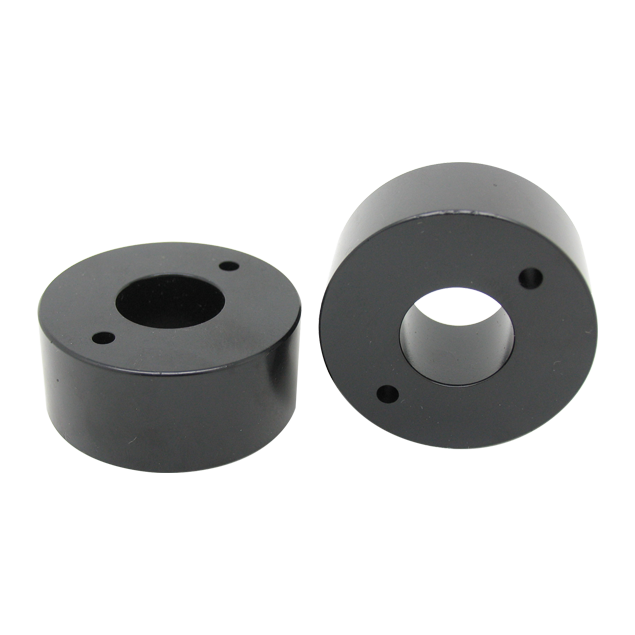

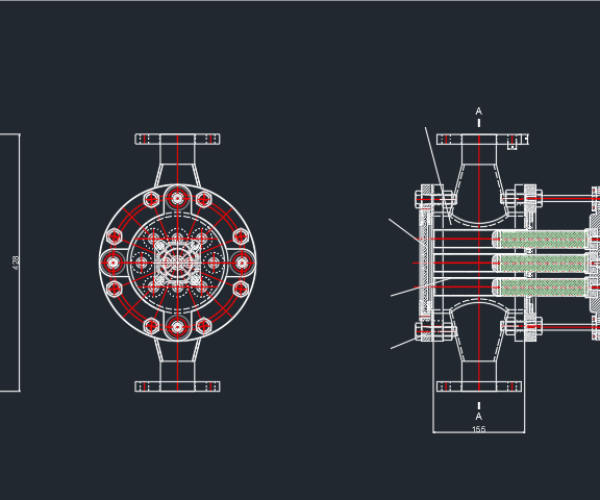

Hygienic Filter JH-W03 by Jin Hong

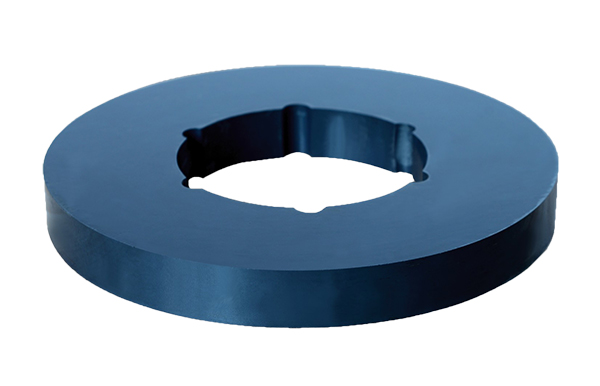

The JH-W03 filter features an optimized magnetic separator design for easy maintenance. It offers semi-automatic cleaning and compatibility with on-site cleaning processes to enable simultaneous cleaning and flushing. Additionally, we offer rotating magnetic filters specifically designed for handling oily powders, helping to prevent powder adhesion on the magnetic rods. These advanced filtration solutions help ensure the removal of metal particles and maintain product purity, meeting the high standards required in the pharmaceutical and food industries.