Paper, Fiber, and Textile Manufacturing

In the paper, fiber, and textile manufacturing industries, metal wires may sometimes get mixed into the pulp, often because the binding wires or straps used to secure cellulose bundles have not been completely removed. These small metal particles can damage the expensive processing equipment used in subsequent pulp processing, leading to production line interruptions. The application of magnetic separation, whether in wet or dry processes, can effectively remove these ferrous contaminants, preventing damage to machinery.

Plastics Industry

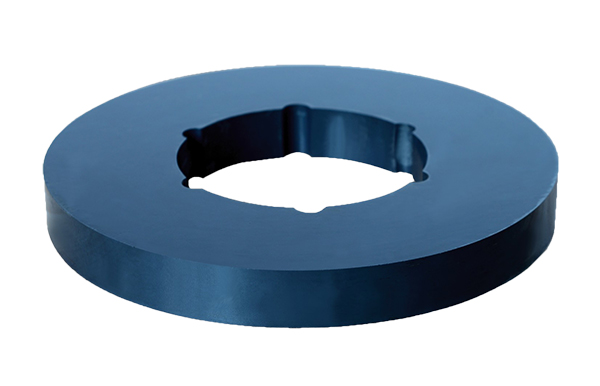

Metal contaminants can harm key machinery components, such as injection molding machines, extruders, screens, mixers, and grinders, causing product quality degradation and production stoppages. In the plastics industries, it is essential to remove ferrous metals and other unwanted metal contaminants to prevent machinery damage and ensure smooth, uninterrupted production. Eddy current separators and magnetic fields can efficiently remove tramp metals and weakly magnetic particles from raw plastics, ensuring that the material remains free from impurities throughout the production process.

Magnetic Filtration Solutions in Pulp Processing

Magnetic filters can remove ferrous particles from paper that is to be converted into cellulose, providing protection to the machinery and preventing unexpected production stoppages. Many large European paper manufacturers have already integrated magnetic filters into their production lines, effectively safeguarding their operations against ferrous materials that could cause equipment damage. These filters use magnetic fields to capture even the finest ferrous particles, ensuring that the final product remains free from contaminants.

Protection Strategy

Magnetic filters serve as a solid "safety net" and should be a standard part of paper, fiber, and textile production lines. They help to remove ferrous and non-ferrous metals from the material, preventing equipment damage and production interruptions, offering a short return on investment. The methods for filtering iron contaminants vary depending on the product structure.

For example, in paper or textile production, the raw materials often appear in clumps. By moistening the product, these clumps can be loosened, making it easier to separate the iron contaminants and metal particles from the final product. Magnetic separation can be especially effective in these cases, providing a reliable method for cleaning materials.

As a result, Jin Hong Company has developed magnetic filters suitable for both wet and dry processes, providing an efficient solution for removing metal contaminants from raw materials, ensuring high-quality end products.

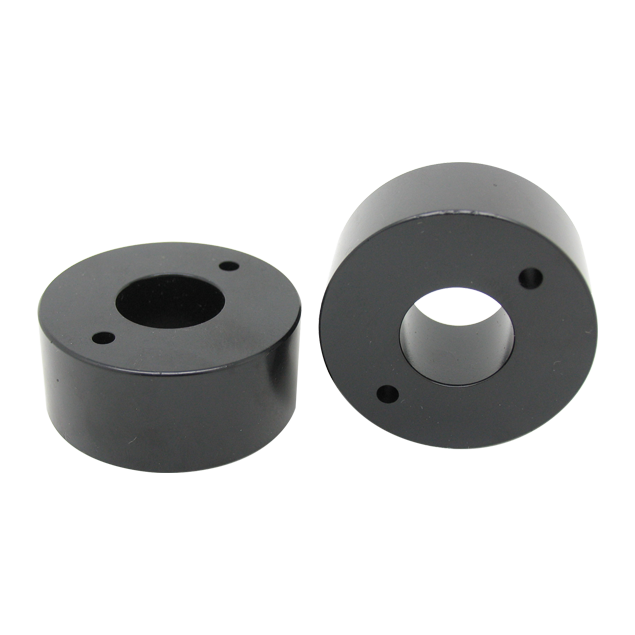

Manual Removal of Metal and Plastic Contaminants Using Magnetic Bars

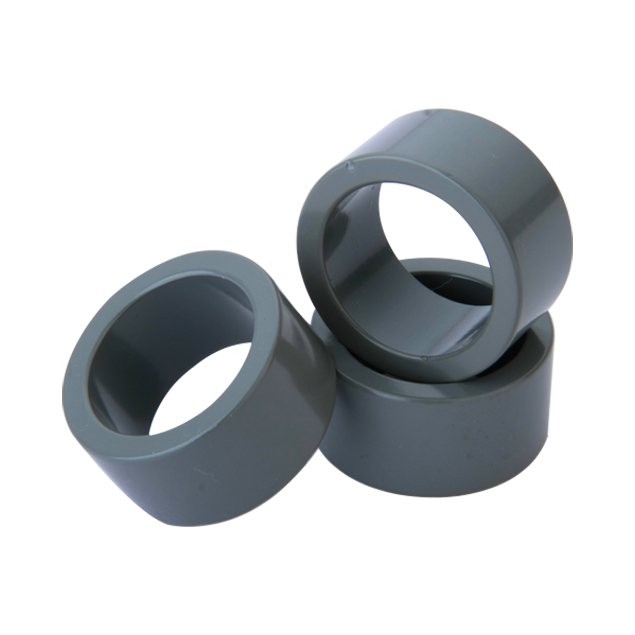

Plastic raw materials are supplied in the form of granules, powders, or fragments, including both recycled and new materials. These materials should not contain unnecessary metal or foreign particles.

Using magnetic bars for manual removal is an effective method for eliminating metal contaminants from these raw materials, ensuring that the plastic remains free from impurities during the production process.

Sources of contamination can vary, including machine wear or damage during processing, or metal particles already mixed into recycled materials that were either not removed or not effectively removed from the original product. Stainless steel contamination is a common issue, particularly in plastics recycling, and must be addressed using high-strength magnetic materials.

Impact of Metal Contamination

Metal or foreign objects in plastics can lead to the following consequences:

Production interruptionsEquipment damageProduct rejectionEven if a product passes inspection, it may still present issues due to undesirable characteristics caused by metal contaminants.

For example, metal contamination in transparent water bottles or baby bottle nipples may seem insignificant but can have catastrophic consequences for both safety and quality.

Processing Methods

Injection molding, extrusion, vacuum or pressure forming, and rotational molding are the most common processes for plastics or thermoplastics. Excess metal contaminants in plastics can clog nozzles or heads. The nozzle's small opening is critical for measuring the plastic, and when contamination occurs, it can block the flow, leading to defects. In the worst cases, this could lead to an entire batch being rejected. Additionally, once a clog occurs, the manufacturer must disassemble and clean the blocked nozzle or, in extreme cases, replace it. This can result in hours or even longer periods of production downtime.

In some instances, contamination may not block the nozzle but may enter between the pump and nozzle and ultimately make its way into the final product. Magnetic separation can prevent these issues by removing ferrous contaminants from the materials before they reach critical processing stages.

Contaminated batches must be isolated for thorough investigation, which helps identify the cause and prevent future contamination. In addition to the investigation's extra costs, products or even entire batches may be rejected.