Magnets are widely used in industries such as electronics, automotive, aerospace, and healthcare. However, not all magnets can withstand high temperatures without losing their magnetic properties. This is where Curie temperature and working temperature come into play.

The Curie temperature (Tc) marks the point where a magnet loses its ferromagnetism and becomes paramagnetic. The working temperature (Tw), on the other hand, determines the safe temperature range within which a magnet can function effectively. Understanding these temperature-related factors is essential for choosing the right magnet for different applications.

In this article, we’ll break down the concepts of Curie temperature and working temperature, discuss how temperature affects magnets, and explore how to select the best magnetic materials based on thermal stability.

What Is Curie Temperature?

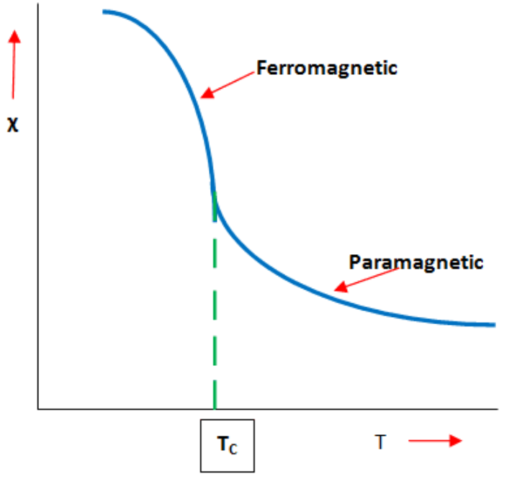

The Curie temperature is a critical property of magnetic materials. Named after the French physicist Pierre Curie, this temperature marks the transition between ferromagnetism and paramagnetism.

Definition:

Curie temperature (Tc) is the temperature at which a magnetic material loses its permanent magnetism and becomes paramagnetic due to molecular instability.

What Happens Above the Curie Temperature?

When the temperature exceeds the Curie point:

-

The internal molecular movement of the magnet becomes intense.

-

Magnetic domains (which are responsible for magnetism) collapse.

-

Ferromagnetic properties such as magnetic permeability, hysteresis loop, and magnetostriction disappear.

-

The magnet undergoes irreversible demagnetization—it can be re-magnetized, but the strength may not return to its original level.

Curie Temperature of Common Magnetic Materials

The Curie temperature varies based on material composition and structure. Here’s a look at some common magnetic materials:

|

Material Type

|

Curie Temperature Tc (°C)

|

Maximum Working Temperature Tw (°C)

|

|

AlNiCo Magnet

|

860

|

550

|

|

Permanent Ferrite

|

450

|

300

|

|

FeCrCo Magnet

|

650

|

500

|

|

SmCo5 Magnet

|

750

|

300

|

|

Sm2Co17 Magnet

|

880

|

450-550

|

|

NdFeB Magnet

|

312

|

230

|

From the table, we can see that materials like AlNiCo and Sm2Co17 magnets have high Curie temperatures, making them more resistant to heat, whereas NdFeB magnets have lower temperature resistance.

What Is Working Temperature?

Working temperature (Tw) is the maximum temperature at which a magnet retains most of its magnetic properties without significant degradation. It’s typically much lower than the Curie temperature.

How Working Temperature Affects Magnet Performance

-

As the temperature rises, magnetic force decreases.

-

In most cases, some magnetism recovers upon cooling, but prolonged exposure to high temperatures can lead to permanent loss.

-

Different materials have different thermal stabilities, influencing their maximum operating temperature.

Working Temperature of Sintered Neodymium Magnets

Neodymium magnets (NdFeB) are popular for their high magnetic strength, but they are sensitive to temperature. Here’s how different grades of NdFeB magnets withstand heat:

|

Magnetic Force Grade

|

Maximum Working Temperature

|

|

N (Normal)

|

80°C

|

|

M (Medium)

|

100°C

|

|

H (High)

|

120°C

|

|

SH (Super High)

|

150°C

|

|

UH (Ultra High)

|

180°C

|

|

EH (Extremely High)

|

200°C

|

|

AH (Aggressively High)

|

230°C

|

For applications requiring higher heat resistance, choosing H, SH, UH, or higher grades ensures better temperature stability.

Relationship Between Working Temperature and Curie Temperature

The higher the Curie temperature, the higher the working temperature of the magnetic material, and the better the temperature stability. Adding elements such as cobalt, terbium, and dysprosium to sintered neodymium-iron-boron materials can improve their Curie temperature. As a result, high coercivity products (H, SH, …) generally contain added dysprosium.

For the same type of magnet, different grades or specifications can have varying temperature resistance due to differences in composition and structure. For example, in the case of neodymium-iron-boron magnets, the maximum working temperature of different grades can range from 80°C to 230°C.

Factors Affecting the Actual Working Temperature of Permanent Magnets

Several factors influence how a magnet reacts to temperature changes:

Shape and Size of the Magnet

Shape and Size of the Magnet (also known as the aspect ratio or magnetic permeability coefficient Pc) have a significant impact on the actual maximum working temperature. Not all H-series neodymium magnets can work at 120°C without losing magnetism. Some magnets may even be demagnetized at room temperature. Therefore, it is necessary to increase the coercivity grade to improve the actual maximum working temperature.

Degree of Magnetic Circuit Closure

Degree of Magnetic Circuit Closure also affects the actual maximum working temperature of the magnet. For the same magnet, the more closed the working magnetic circuit, the higher the maximum working temperature and the more stable the magnet’s performance. Therefore, the maximum working temperature of the magnet is not a fixed value, but varies depending on the degree of closure of the magnetic circuit.

Choosing the Right Magnet Based on Temperature Needs

Choosing the ideal magnet depends on the specific temperature range of your application. For environments where temperatures exceed 200°C, magnets like Sm2Co17, AlNiCo, and FeCrCo are best suited, as they offer exceptional heat resistance. For moderate temperatures between 100°C and 200°C, Neodymium magnets in H, SH, or UH grades work well, providing a balance of strength and heat tolerance. For temperatures below 100°C, standard NdFeB (N or M grade) or Ferrite magnets will suffice. Always consider the temperature your magnet will experience and choose a material that guarantees long-term stability and performance in those conditions.

Conclusion

In conclusion, understanding the Curie and working temperatures of magnets is essential for selecting the right material for specific applications. The Curie temperature marks the point where a magnet loses its magnetism, while the working temperature defines the range within which it remains effective. Factors like the magnet’s shape, size, and the degree of magnetic circuit closure can impact its actual working temperature. Companies like Jinhong specialize in producing high-quality magnets with precise Curie temperatures and working temperature capabilities, ensuring stability and reliability for various applications. Choosing the right material can enhance performance and durability in real-world conditions.