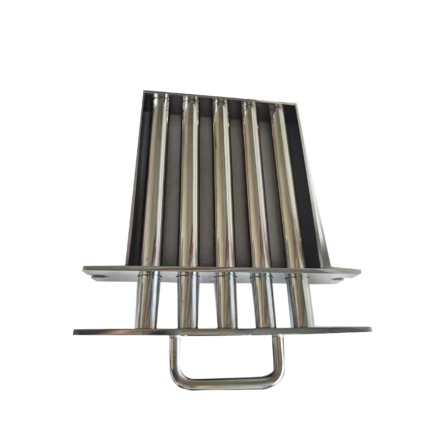

Magnetic Pulley Description

The Magnetic Pulley is an essential component in automated iron separation systems, designed for efficient and continuous removal of ferrous contaminants. It is ideal for processing large volumes of bulk materials across a variety of industries, ensuring product quality and operational efficiency.

Applicable Uses

The Magnetic Pulley is perfect for handling materials that may contain iron filings, flakes, or blocks. Common applications include:

- Mining & Mineral Processing: Separation of iron ore from sand, gravel, and other minerals.

- Food Processing: Removal of iron contaminants from grains, powders, and raw materials.

- Recycling: Eliminates iron particles from plastics, wood chips, glass, and other recyclable materials.

- Construction: Captures iron debris like nails or fragments in sand, concrete mix, or gravel.

- Pharmaceuticals & Chemicals: Ensures product purity by removing iron contaminants from powders and bulk materials.

Key Features

1. Magnetic Material Options

- Equipped with ferrite permanent magnets (cost-effective) or rare earth permanent magnets (super-strong).

- Achieves a magnetic field strength of up to 15,000 GS, ideal for separating fine and coarse iron particles.

2. Corrosion-Resistant Construction

- Made from 304 or 316L stainless steel, providing:

- Excellent resistance to corrosion.

- Durability in harsh industrial environments.

- Pollution-free operation to protect material integrity.

3. Energy-Efficient Magnetic Field

- Permanent magnet design eliminates the need for electricity, resulting in a cost-effective and eco-friendly solution.

4. Motorized Operation

- Pulley ends are motor-compatible for seamless integration into automated systems.

- Ensures smooth and continuous material flow for efficient iron separation.

5. Automatic Separation System

- When paired with a pipe belt conveyor, it creates a fully automated system that:

- Eliminates the need for manual intervention.

- Streamlines the process for high-speed, high-volume operations.

6. Customizable Design

- Fully customizable to meet specific requirements, including:

- Size and shape adjustments.

- Tailored magnetic strength for unique materials or processing needs.

Advantages

- Efficient Iron Removal:

- High magnetic strength ensures precise and thorough removal of iron contaminants.

- Low Operating Costs:

- Permanent magnets require no power, reducing energy consumption.

- Durability and Reliability:

- Stainless steel construction ensures long service life even in harsh environments.

- Streamlined Automation:

- Supports continuous, unattended operation, enhancing productivity.

- Customizable for Versatility:

- Adaptable to meet specific material and operational demands across diverse industries.

Applications

Industries

- Mining and Minerals: Ensures high-quality separation of iron from valuable minerals.

- Food Production: Guarantees food safety by removing metal contaminants.

- Recycling: Improves the purity of recyclable materials.

- Construction: Captures metal debris, improving material quality.

- Pharmaceuticals and Chemicals: Maintains hygiene and purity standards by eliminating metal contamination.

Summary

The Magnetic Pulley is a powerful and reliable solution for automated iron separation in bulk material processing. Its energy-efficient design, strong magnetic field, and customizable features make it suitable for a wide range of industrial applications. With the ability to handle large volumes, it ensures consistent product quality and operational efficiency while minimizing manual intervention and operational costs.

For customized designs and detailed specifications, feel free to contact us!