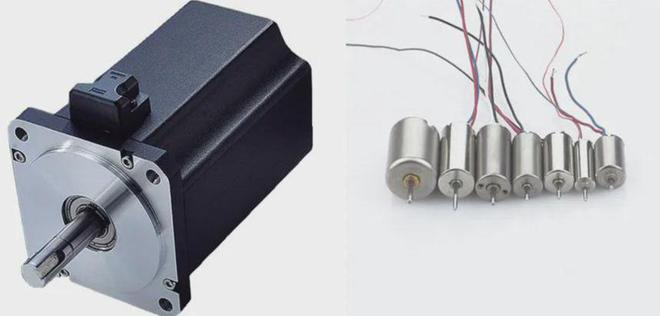

When it comes to electric motors, two prominent types—hollow cup motors and permanent magnet motors—often stand out due to their unique design and performance features. Hollow cup motors, with their lightweight and compact structure, are renowned for their high efficiency and ability to deliver precision in applications like robotics and drones. On the other hand, permanent magnet motors, leveraging the power of magnets for consistent torque and energy efficiency, are commonly used in industries ranging from automotive to home appliances.

Both motor types have their advantages and applications, but understanding their differences is crucial in selecting the right motor for specific needs. In this article, we will delve into the key comparisons between hollow cup and permanent magnet motors, helping you make an informed decision for your next project. Additionally, we’ll explore how magnetic separation technologies from companies like Jinhong play an essential role in improving motor efficiency and performance across various industries.

What is a Hollow Cup Motor?

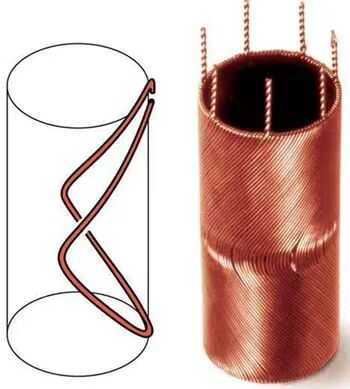

A hollow cup motor is a type of electric motor characterized by its unique, lightweight design. Unlike traditional motors, which typically feature a central rotor, a hollow cup motor has a rotor that forms a cup-like shape, hence the name. This design significantly reduces the motor’s weight and volume, making it ideal for applications where space and weight are critical factors, such as in drones, robotics, and other precision devices.

The hollow cup motor operates on the principle of electromagnetic induction, where the interaction between the magnetic field and current in the motor coils generates torque. What sets it apart from conventional motors is its compact, high-efficiency design, which allows for faster acceleration, better energy efficiency, and higher power-to-weight ratios. These advantages make hollow cup motors especially useful in applications that demand both high performance and miniaturization.

What is a Permanent Magnet?

A permanent magnet is a type of magnet that generates a constant magnetic field without the need for external power sources or electrical input. Unlike electromagnets, which require an electric current to produce a magnetic field, permanent magnets retain their magnetism indefinitely, making them reliable and efficient for various applications. This natural magnetic property arises from the alignment of the magnetic domains within the material, which are typically made of metals like iron, cobalt, nickel, or rare earth elements.

Permanent magnets are commonly used in a wide range of devices, from motors and sensors to speakers and magnetic separation equipment. In motors, the permanent magnets provide a steady magnetic field that interacts with the electric current in the motor’s coils, generating torque and enabling motion. These motors are often preferred for their simplicity, durability, and energy efficiency, especially in applications like electric vehicles, household appliances, and industrial machinery.

Key Differences Between Hollow Cup Motors and Permanent Magnets

When selecting the right motor for a specific application, understanding the differences between hollow cup motors and permanent magnet motors is crucial.In this section, we’ll explore the key distinctions between these two motor types, helping you make an informed decision based on your project’s specific needs.

1. Design and Structure

Hollow cup motors are characterized by their unique rotor design, which is shaped like a hollow cup. This design makes them incredibly lightweight and compact, ideal for applications where saving space and reducing weight are essential. The rotor is surrounded by a stator that generates the magnetic field needed to drive the motor.

On the other hand, permanent magnet motors use magnets that are permanently magnetized and placed on the rotor. The stator interacts with these magnets to produce torque. This design is often more robust but heavier compared to hollow cup motors, making it suitable for applications where size is important but weight isn’t as critical.

2. Efficiency and Power-to-Weight Ratio

Hollow cup motors excel in efficiency, particularly due to their lightweight rotor, which allows for rapid acceleration and reduced energy consumption. The minimal friction and low inertia in these motors contribute to a higher power-to-weight ratio, making them ideal for precision applications like robotics and drones. Permanent magnet motors also offer excellent efficiency, as the permanent magnets reduce the energy required to generate the magnetic field. However, their power-to-weight ratio is generally lower than that of hollow cup motors due to the heavier permanent magnets used in their construction.

3. Applications

Hollow cup motors are commonly used in compact devices that require precise control and minimal weight, such as drones, miniature robots, and medical instruments. Their ability to deliver quick, accurate movements makes them perfect for high-performance applications where space constraints are critical. Permanent magnet motors, with their reliable torque and energy efficiency, are widely used in larger-scale applications, such as electric vehicles, home appliances, and industrial machinery. Their durability and consistent performance make them well-suited for applications where higher torque and longer operational lifetimes are needed.

4. Cost and Manufacturing

Hollow cup motors are typically more expensive to produce due to the specialized manufacturing processes required to create their lightweight, compact design. The high precision needed in their construction often makes them costlier, especially for niche applications. In contrast, permanent magnet motors are generally less expensive to produce, though the cost of materials like rare-earth magnets can drive up the price in some cases. Overall, permanent magnet motors tend to be more cost-effective for mainstream applications, though the choice of magnets and manufacturing techniques can affect their overall cost.

5. Maintenance and Durability

Hollow cup motors have fewer moving parts and a lightweight design, which translates to less wear and tear over time. This makes them relatively low-maintenance and highly durable in precision-driven environments. Their compact nature also means they can withstand demanding conditions with minimal degradation. Permanent magnet motors, while also durable, may require more maintenance due to potential wear on the rotor and stator. Additionally, the permanent magnets can degrade or lose their magnetism over time, especially in high-temperature environments, which may require more frequent servicing or replacement.

Benefits and Drawbacks of Each Technology

Understanding the benefits and drawbacks of hollow cup motors and permanent magnet motors is essential when choosing the right technology for your application. Each offers distinct advantages and limitations based on factors like efficiency, size, and cost.

Pros and Cons of Hollow Cup Motors

Pros:

- Lightweight and Compact Design: Hollow cup motors are exceptionally lightweight, making them ideal for applications where minimizing weight and space is critical, such as in drones, small robots, or medical devices.

- High Power-to-Weight Ratio: The unique rotor design reduces inertia and friction, allowing for rapid acceleration and greater efficiency, particularly in precision tasks.

- Efficient Performance: Their compact structure allows for better energy efficiency, as the reduced weight means less energy is needed to operate, making them perfect for battery-powered devices.

- Low Maintenance: With fewer moving parts, hollow cup motors generally require less maintenance over time, reducing the cost and hassle of upkeep.

Cons:

- Higher Production Costs: The specialized manufacturing required for hollow cup motors can make them more expensive to produce, particularly for niche applications.

- Limited Torque Output: While they excel in high-speed precision, hollow cup motors typically generate less torque compared to other motor types, limiting their use in heavy-duty or high-torque applications.

- Less Durability in Harsh Conditions: The lightweight nature of hollow cup motors might make them less durable in extreme environments or heavy-duty industrial settings where motors are subjected to high stress.

Pros and Cons of Permanent Magnet Motors

Pros:

- High Efficiency: Permanent magnet motors are highly efficient, as the permanent magnets reduce the energy required to generate the magnetic field. This leads to less energy consumption and better overall performance in many industrial and consumer applications.

- Reliable Torque: The magnets provide a consistent and steady torque, making permanent magnet motors ideal for applications that require reliable, long-term performance, such as in electric vehicles and large machinery.

- Durability: Permanent magnet motors have fewer wear points and can operate for longer periods with minimal degradation, making them well-suited for high-demand environments.

- Cost-Effective for Mainstream Applications: While they can be expensive depending on the materials used, permanent magnet motors are generally more cost-effective than hollow cup motors for large-scale, mainstream applications.

Cons:

- Higher Weight: Due to the use of permanent magnets, these motors tend to be heavier than hollow cup motors, making them less suitable for applications where minimizing weight is a priority.

- Cost of Materials: Permanent magnet motors often use rare-earth magnets, such as neodymium, which can be costly. The price of these materials can make the motors more expensive, especially in high-performance models.

- Sensitivity to Heat: Permanent magnets can lose their magnetic properties when exposed to high temperatures, which may affect the motor’s efficiency and lifespan. This makes them less suitable for extreme temperature environments unless specifically designed for high-heat tolerance.

- Maintenance: While generally durable, permanent magnet motors can still require maintenance, particularly in harsh industrial settings where magnets might degrade over time or where the rotor and stator experience wear.

Conclusion

In conclusion, both hollow cup motors and permanent magnet motors offer distinct advantages depending on the application. Hollow cup motors shine in lightweight, space-constrained environments where precision and efficiency are paramount, making them ideal for drones, robotics, and battery-powered devices. On the other hand, permanent magnet motors provide reliable torque and efficiency, excelling in heavy-duty, long-term applications like electric vehicles and industrial machinery.

When selecting the right motor, it’s essential to weigh the specific requirements of your project, whether that’s size, efficiency, torque, or cost. Additionally, magnetic separation technologies from companies like Jinhong can play a crucial role in enhancing motor performance by improving material handling and minimizing impurities in the manufacturing process. Ultimately, understanding the strengths and limitations of each motor type will help you make a more informed decision for your application.