Magnetic fields are integral to a wide range of applications in both engineering and science. Understanding the difference between surface magnetic field and magnetic flux is crucial for designing and optimizing devices that rely on magnets, from electric motors to medical equipment. Companies like Jinhong, a leader in magnetic separation technologies, leverage these principles to enhance the performance of their systems. In this article, we will explore these two key concepts, their differences, and their practical applications.

What is the Surface Magnetic Field?

The surface magnetic field is a measure of the magnetic flux density at a specific point on the surface of a magnet. Essentially, it tells you the strength of the magnetic field at that location. This value is typically measured in units of Gauss (Gs) or Tesla (T). To measure it accurately, instruments like Gaussmeters or Hall-effect sensors are used.

How Surface Magnetic Field Works

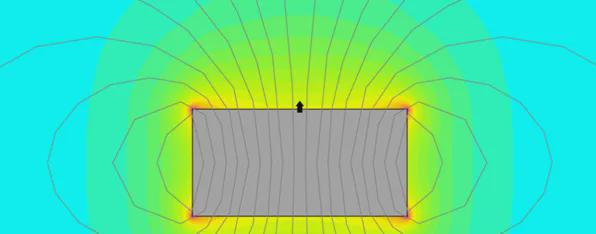

The strength of the surface magnetic field varies at different points on the surface of a magnet. Because the magnetic field distribution of a magnet is not uniform, the value of the surface magnetic field can be different depending on the location where it’s measured. This makes the surface magnetic field particularly important in applications where spatial distribution of the magnetic field is critical.

For example, the surface magnetic field of a magnet is influenced by its aspect ratio (the ratio of its height to its diameter). A larger aspect ratio generally results in a stronger surface magnetic field, because the dimension along the magnetization direction increases, concentrating the field. Conversely, a magnet with a smaller aspect ratio will have a weaker surface magnetic field.

What is Magnetic Flux?

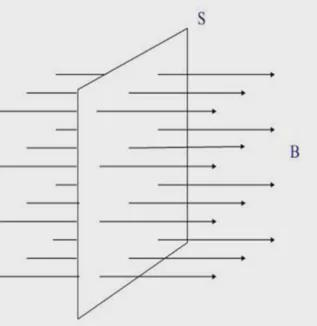

Magnetic flux is the total amount of magnetic field passing through a given area. It measures the overall strength of a magnet or magnetic assembly. Magnetic flux is measured in Webers (Wb), and it is essential for understanding how a magnetic field interacts with the surrounding environment, such as in motors, transformers, or magnetic storage devices.

How Magnetic Flux is Measured

Magnetic flux is measured using a fluxmeter, which works by detecting the magnetic field passing through a coil. When used alongside a Helmholtz coil, the fluxmeter can measure the total magnetic flux with great accuracy. A Helmholtz coil is specifically designed to produce a uniform magnetic field, making it ideal for precise flux measurements.

It’s important to note that while magnetic flux gives the total field strength, it is not the same as the magnetic moment of a magnet, which represents the strength and direction of the magnetic field. Magnetic flux can vary depending on the measurement setup, but the magnetic moment remains constant for a given magnet.

Magnetic Remanence: A Key Concept in Magnetism

Magnetic remanence refers to the persistent magnetization a material retains after an external magnetic field is removed. Essentially, it is the intrinsic magnetization that remains within the material even after the external influences, like an applied magnetic field, have been taken away. This property is particularly important in permanent magnets, as it determines their ability to maintain their magnetization without requiring a continuous external magnetic source.

Magnetic remanence is typically measured in a closed-circuit state, meaning the magnet’s magnetic field is fully contained and not exposed to external forces or interference. In this state, the magnet retains a certain amount of magnetism that is inherent to its material composition and manufacturing process. However, this magnetization can change under certain conditions, such as exposure to high temperatures or mechanical shock, which may lead to self-demagnetization.

Key Differences Between Surface Magnetic Field and Magnetic Remanence

|

Property

|

Magnetic Remanence

|

Surface Magnetic Field

|

|

Definition

|

Permanent magnetization after external field is removed.

|

Local magnetic flux density at a specific point on the surface.

|

|

Measurement State

|

Measured in a closed-circuit state.

|

Measured at specific surface points, often in an open-circuit state.

|

|

Stability

|

Remains constant unless demagnetized.

|

Varies across the surface of the magnet.

|

|

Value

|

Typically constant for a given magnet.

|

Generally, half the value of remanence for a single magnet.

|

|

Material Dependency

|

Intrinsic to the material’s composition.

|

Can vary depending on the magnet’s shape and design.

|

|

Effect of Magnetic Circuit

|

Not influenced by magnetic circuit design.

|

Can be enhanced or altered by special magnetic circuit designs.

|

While both properties are crucial in understanding a magnet’s behavior, they serve different roles. Magnetic remanence is a fixed characteristic that tells you how strongly a material is magnetized overall, while the surface magnetic field provides localized measurements of magnetic strength at specific points on the magnet’s surface.

In magnetic assemblies or systems using magnetic circuits, the surface magnetic field can be enhanced, sometimes exceeding the remanence. This is because magnetic circuits are designed to direct and concentrate the magnetic flux at specific points, improving the effectiveness of the magnetic field in those areas.

The Role of Fluxmeter and Helmholtz Coil

The fluxmeter is a critical tool used for measuring magnetic flux, and when combined with a Helmholtz coil, it enables precise measurement of the magnetic field in a controlled environment. This setup is invaluable for determining the total magnetic flux and calculating the magnetic moment of a magnet. The Helmholtz coil produces a uniform field, which helps minimize measurement errors, ensuring that the fluxmeter reads the total flux accurately.

The Helmholtz coil creates a stable, predictable magnetic field that is used to measure magnetic flux. As the magnetic flux passes through the coil, the fluxmeter records the strength of the field. This combination is especially useful in laboratories and high-precision applications, where exact magnetic measurements are critical.

Magnetic Circuits: Enhancing Magnet Efficiency

A magnetic circuit is essentially the path that magnetic flux takes through a system, usually made up of one or more permanent magnets and ferromagnetic materials. These materials help direct and concentrate the magnetic flux, improving the efficiency of the system. For instance, in electric motors or generators, the magnetic circuit ensures that the magnetic flux is used effectively to generate power.

In a magnetic circuit, ferromagnetic materials like iron or steel play an important role. These materials help increase the local flux density and guide the magnetic field along specific paths. In turn, this can improve the surface magnetic field strength and make the system more efficient. For example, in a motor, a well-designed magnetic circuit can ensure that the surface magnetic field is maximized, increasing the efficiency of the motor.

Practical Applications of Surface Magnetic Field and Magnetic Flux

The concepts of surface magnetic field and magnetic flux are essential for many practical applications, particularly those that involve permanent magnets or magnetic assemblies.

Electric Motors

In electric motors, both surface magnetic field and magnetic flux are crucial for generating the electromagnetic forces needed to power the motor. A stronger surface magnetic field results in a more efficient motor, while the overall magnetic flux determines the motor’s strength.

Magnetic Storage

Magnetic flux plays a key role in magnetic storage devices like hard drives. The magnetic flux density is used to store data, while the surface magnetic field helps to read and write information accurately.

Medical Devices (MRI)

In magnetic resonance imaging (MRI) machines, understanding magnetic flux is essential to generating the strong magnetic fields required for imaging. The surface magnetic field is also important for ensuring that the magnets interact correctly with the human body.

Measuring Surface Magnetic Field and Magnetic Flux

Measuring both surface magnetic field and magnetic flux requires specialized equipment and careful attention to measurement techniques. While Gaussmeters and Hall-effect sensors are used for surface magnetic field measurements, fluxmeters and Helmholtz coils are used for measuring magnetic flux.

Key Instruments for Measurement:

-

Gaussmeter: Used to measure the surface magnetic field at specific points on a magnet’s surface.

-

Fluxmeter: Measures the total magnetic flux passing through a coil.

-

Helmholtz Coil: Used in conjunction with a fluxmeter to ensure uniform magnetic field conditions during measurement.

Conclusion

Grasping the fundamental concepts of surface magnetic field and magnetic flux is crucial for the effective design, optimization, and application of magnets in diverse industries. By accurately measuring and understanding these properties, engineers and scientists can improve the performance and efficiency of magnetic systems. Companies like Jinhong, with its advanced magnetic separation technology, leverage these principles to create more effective and durable solutions for industrial challenges, ensuring better results across various sectors.

FAQs About Surface Magnetic Field and Magnetic Flux

-

How is magnetic flux different from surface magnetic field?

Magnetic flux refers to the total amount of magnetic field passing through an area, while surface magnetic field measures the intensity of the magnetic field at a specific point on a magnet’s surface.

-

Why is the surface magnetic field important?

The surface magnetic field is important because it helps determine the strength and efficiency of magnets used in various applications, including motors, sensors, and storage devices.

-

What instruments are used to measure surface magnetic field?

Surface magnetic field is typically measured using a Gaussmeter or Hall-effect sensor.

-

How does magnetic flux affect performance in motors?

Magnetic flux is directly related to the strength of the magnetic field in a motor. A higher magnetic flux means a stronger field, which improves the efficiency and power output of the motor.

-

What role do magnetic circuits play?

Magnetic circuits help control the direction of magnetic flux, increase flux density, and improve the overall efficiency of magnetic systems, such as motors and generators.