In the food industry, maintaining product safety and quality is paramount. One of the critical processes that ensures this is magnetic separation. This method plays a key role in removing ferromagnetic contaminants from raw materials and finished products, safeguarding consumers from potential health hazards. Metal fragments can enter food products at various stages of production—from, handling, and processing, to packaging. Even the smallest particles, if not detected and removed, can pose serious risks to both the consumer and the manufacturer, including costly product recalls and reputational damage.

Magnetic separation is an efficient solution to this issue. By using powerful magnets, the process captures and removes these unwanted metal contaminants, ensuring that the final product meets stringent food safety standards. This method is particularly crucial for industries dealing with bulk materials, where contamination risks are higher. With the implementation of magnetic separation in processing lines, food manufacturers can guarantee higher product purity, reduce production downtime, and ensure regulatory compliance—all of which are essential for maintaining consumer trust and industry credibility.

Why Magnetic Separation Is Important?

Magnetic separation is crucial in the food industry because it ensures product safety and quality by removing ferromagnetic contaminants from the production line. Even small metal fragments, such as iron or steel, can find their way into food products during processing, packaging, or transportation. These contaminants can pose serious health risks to consumers and lead to costly recalls and reputational damage for manufacturers. By using powerful magnets to capture and remove these metal particles, magnetic separation helps prevent such issues from occurring. Additionally, this process is an effective way to meet food safety regulations, including those set by HACCP and the FDA. Magnetic separators also help protect machinery by preventing metal contaminants from damaging equipment, which can cause production downtime and costly repairs. Overall, magnetic separation is an essential tool for ensuring that food products remain free from harmful contaminants, thereby maintaining consumer trust and protecting the integrity of the brand.

How Does Magnetic Separation Work in the Food Industry?

Magnetic separation in the food industry works by using powerful magnets to remove ferromagnetic contaminants, such as iron or steel, from raw materials or processed products. This process is crucial in maintaining product safety and quality, preventing hazardous metal fragments from reaching consumers. Here’s how it typically works:

- Placement of Magnets

- Attraction of Metal Contaminants

- Separation of Contaminants

Magnetic separators are placed at key points along production lines, where raw materials or finished products pass through. These separators, in the form of magnetic plates, grids, tubes, or drums, create a magnetic field that captures any ferromagnetic particles, such as iron or steel, that may be present in the material.

As food products move along conveyors or processing equipment, the magnets attract and hold these metal contaminants, preventing them from continuing along the production line. This ensures that no harmful metal fragments end up in the final product.

The trapped metal particles remain secured by the magnets while the clean food products pass through. Depending on the type of magnetic separator, the contaminants are either manually or automatically removed. This process not only guarantees food safety but also helps maintain product quality by preventing metal contamination, making magnetic separation an essential part of modern food production.

Common Magnetic Separation Equipment in the Food Industry

Magnetic separation is widely used in the food industry to remove ferromagnetic contaminants and ensure product purity. Here are some of the commonly used magnetic separation equipment:

Plate Magnets

Plate magnets are flat magnetic devices installed in chutes or conveyor belts. They are designed to remove metal contaminants from dry materials like grains, seeds, or powders. As the materials pass over or beneath the magnetic plate, any metal particles are attracted and held in place. This method is effective for handling high volumes of dry ingredients, ensuring a clean final product.

Grate Magnets

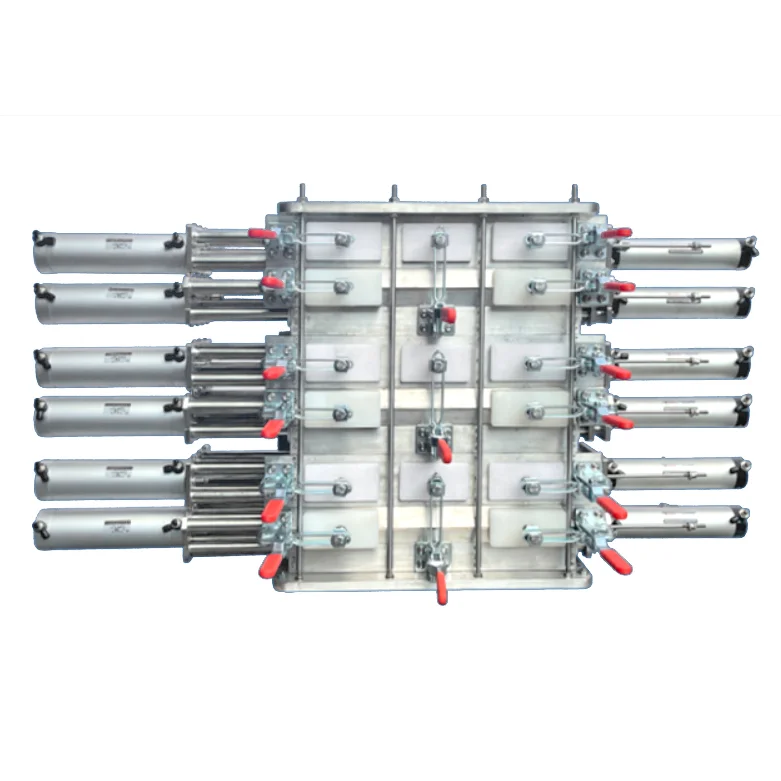

Grate magnets consist of several magnetic bars arranged in a grid-like formation, allowing the product to flow through while capturing any metal particles. These magnets are commonly used in dry ingredient applications such as flour, grain, sugar, and spices. As the product moves through the grate, ferrous contaminants are captured by the magnetic bars. Grate magnets come in various configurations to suit different types of products and processing needs.

Rod Magnets

Rod magnets are cylindrical magnets that are installed in processing lines to capture metal contaminants from powdered or granular materials. They are often used in food processing lines that require high sensitivity to metal contamination. Rod magnets are easy to clean and maintain, making them suitable for continuous production environments.

Liquid Line Trap Magnets

Liquid line trap magnets are designed for wet food products such as sauces, liquids, or slurries. These magnets are installed in pipelines and create a magnetic field that captures ferrous particles as the liquid flows through. This ensures that even liquid products are kept free from metal contamination.

Suspend Magnets

Suspend magnets are used above conveyor belts to remove larger metal contaminants before the materials proceed to the next stage of production. These powerful magnets are suspended over the production line, capturing metal particles from bulk materials as they move along the conveyor. Suspend magnets help protect downstream equipment and ensure that large metal pieces are removed early in the process.

Factors Influencing Magnet Performance

Several factors influence the efficiency of magnetic separation in food processing, including temperature, product flow, and equipment design. Understanding how these elements interact can help optimize the separation process and improve overall product safety and quality.

1. Temperature

Magnetic materials lose strength when exposed to high temperatures. Once a magnet is heated beyond a specific threshold, it can suffer permanent strength loss that cannot be restored, even if cooled. When dealing with food processing environments involving high temperatures, it’s essential to choose magnets made from materials that can withstand these conditions without losing efficiency.

Flow Characteristics

The flow characteristics of food products can vary based on moisture content. For instance, damp sugar may clump together, potentially causing blockages in the magnetic separator. This obstructs the flow through magnetic tubes and hinders the separation process. Ensuring that the food product can move freely through the separator is critical to maintaining separation efficiency.

2. Equipment Design

The design of the magnetic separation equipment plays a significant role in its effectiveness. Factors like the number of magnetic tubes and the spacing between them determine the strength of the magnetic field generated. Closer spacing and additional tubes create a stronger magnetic field, which in turn leads to better separation of ferromagnetic contaminants.

3. Flow characteristics

Many food products behave differently when they are damp or moist. For example, sugar with high moisture content can clump together and form large particles, which may block the opening of a magnetic separator. This can hinder the product from flowing smoothly through the magnetic tubes.

4. Product Characteristics

The type of food product being processed also affects the performance of magnetic separators. Food products are typically categorized as dry, liquid, or moist, and each type requires specific magnetic separation techniques.

- Dry Products: These range from small grains to larger, rock-like materials moving along conveyor belts. Depending on the product, different separators may be used. Grate magnets are effective for small, free-flowing products, while plate magnets are suitable for materials cascading down sloped chutes. Suspended magnets work well with dry products transported by conveyor belts.

- Liquid Products: For food products in liquid or slurry form, magnetic traps—designed with magnetic tubes arranged perpendicular to the flow—are often used. These traps capture ferrous contaminants as the liquid flows through the system.

- Moist Products: Products like flour or starch, which are prone to clumping, do not flow well through traditional grate magnets. In such cases, using a powerful magnet positioned outside the product flow can prevent buildup and allow for smoother processing. A magnetic rotation system outside the product line is ideal for preventing blockages.

How to Optimize Magnet Performance in Food Processing with Jinhong Solutions

Optimizing magnet performance in food processing is key to maintaining product purity and ensuring effective removal of metal contaminants. With Jinhong’s tailored magnetic separation solutions, you can address factors like temperature, product flow, and equipment design to ensure efficient operation.

Jinhong offers customized magnetic separation systems, selecting magnets that can withstand temperature changes without losing strength. This is particularly useful in high-temperature processes. Jinhong also considers product flow characteristics, offering solutions for both dry and wet food products, ensuring that materials pass through the magnetic field smoothly, avoiding clogging or product buildup.

Additionally, Jinhong’s magnetic separators are designed with optimal spacing and magnetic tube configurations to enhance the strength of the magnetic field. Whether you are handling powders, liquids, or sticky materials, Jinhong provides solutions that improve separation efficiency, helping to maintain product purity while minimizing production delays. Through their in-house design and manufacturing, Jinhong ensures that their equipment delivers reliable performance in your food processing line.

Conclusion

In conclusion, magnetic separation plays a vital role in ensuring the safety and quality of food products. By removing metal contaminants from production lines, it helps protect consumers from potential harm and prevents costly product recalls. Whether dealing with dry, wet, or moist products, magnetic separation provides a reliable solution for maintaining product purity. With Jinhong’s comprehensive and tailored magnetic separation systems, food manufacturers can address key factors such as temperature, product flow, and equipment design, ensuring an efficient and effective process. Jinhong’s commitment to customized solutions, in-house production, and certified quality assurance makes them a trusted partner for optimizing magnet performance in food processing.