Pneumatic Hammer Main Features

- Pneumatic Hammer Versatile Installation

- This Pneumatic Hammer is suitable for installation in circular and square pipelines, especially upstream of magnetic separators or on the outer side of feed hoppers. It can also be adapted for other required installation locations.

- Pneumatic Discharge System

- The device uses the impact force generated by a vibrator to move the screen mesh, effectively breaking up powder clumps and addressing the problem of powder caking.

- Compared to traditional pneumatic hammers, this system offers the following advantages:

- Low noise

- Easy cleaning

- Convenient maintenance

- Low operating costs

- JH-QZ01 Series Specifications

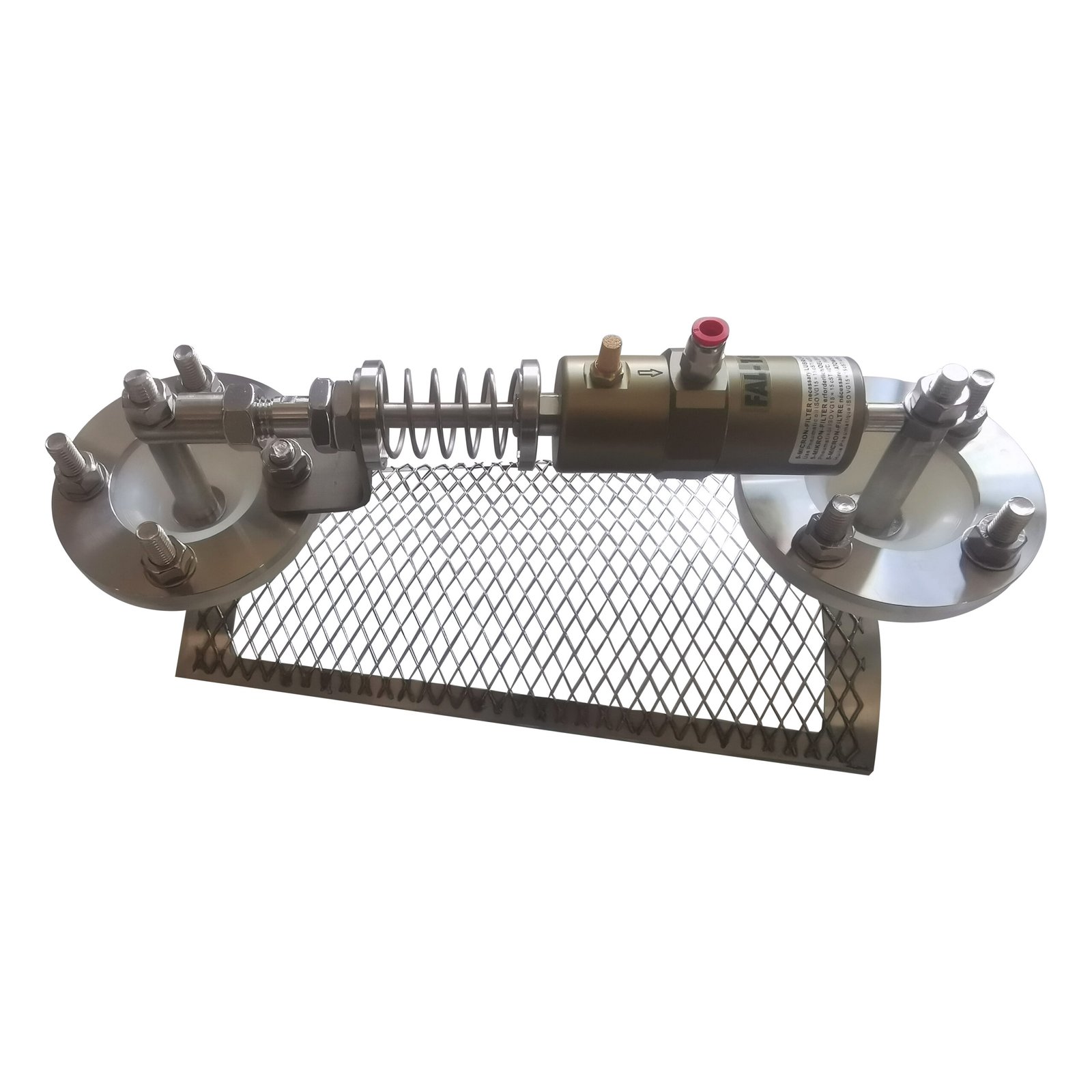

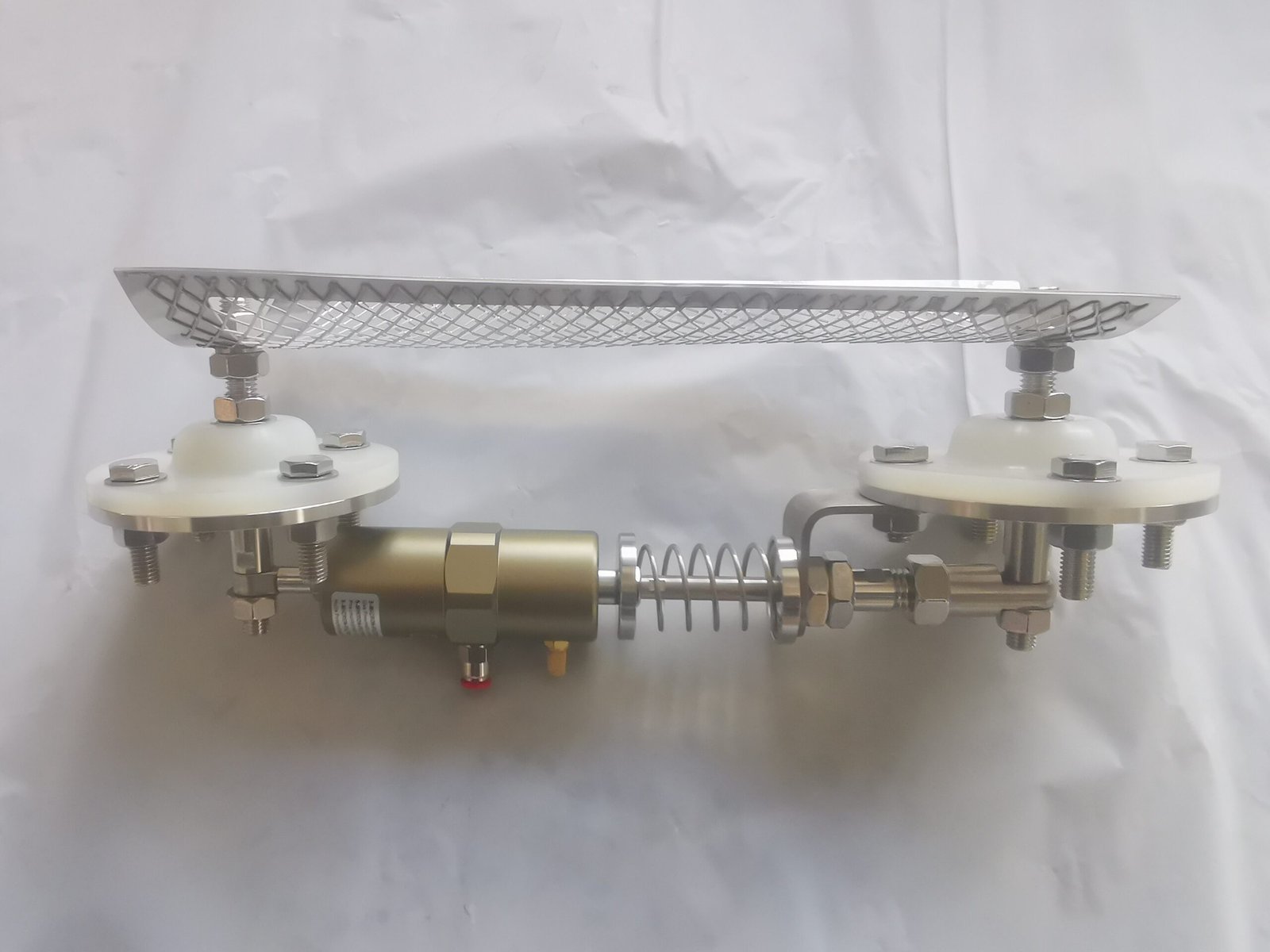

- QZ01: Each unit includes:

- 2 flanges

- 2 shock-absorbing silicone sheets

- 1 vibrator

- 1 vibrating screen

- Dimensions: 450mm × 200mm × 160mm

- QZ01: Each unit includes:

- Customizable Options

- Available in a variety of calibers to suit different pipeline sizes.

- Non-standard designs can be provided based on user requirements to meet diverse operational needs.

(Note: Dimensional parameters are for reference only. Please refer to the factory inspection report or order contract for exact specifications.)

Advantages

- Efficient solution for breaking up powder caking.

- Ideal for pre-magnetic separation processes or feed preparation.

- Customizable to fit different industrial needs.

- Quiet operation and easy maintenance ensure high productivity with minimal disruption.

This pneumatic discharge system is a reliable, cost-effective, and versatile solution for industries handling powdery materials, ensuring smoother operations and enhanced processing efficiency.