Magnetic materials are fundamental to a wide range of industries, including manufacturing, electronics, and healthcare. Understanding the different types of magnetic materials is crucial for selecting the right material for specific applications, from magnetic separation to electronic devices. In this blog, we’ll dive into the main types of magnetic materials—ferromagnetic, paramagnetic, diamagnetic, and others—exploring their distinct properties, behavior in magnetic fields, and real-world uses.

Each type of magnetic material offers unique advantages depending on the task at hand, whether it’s enhancing performance in industrial processes, improving the efficiency of medical devices, or optimizing research applications. By understanding these materials, you’ll be better equipped to make informed decisions and ensure your projects run smoothly and efficiently. Whether you’re new to magnetic materials or looking to deepen your knowledge, this guide will help you navigate their diverse applications.

What Are Magnetic Materials?

Magnetic materials are substances that respond to magnetic fields, either by being attracted to or repelled by them. These materials exhibit varying degrees of magnetic behavior, making them essential in many applications, from electric motors and transformers to medical imaging and magnetic storage devices. Magnetic materials are categorized based on their response to magnetic fields, which is determined by the alignment of their atomic or molecular magnetic moments.

There are several types of magnetic materials, each with distinct properties. Some materials, like iron, are strongly attracted to magnets, while others, like copper, do not exhibit any significant magnetic attraction. The key difference lies in how these materials interact with magnetic fields, leading to a wide range of practical uses in industries such as manufacturing, electronics, and environmental science. Understanding the different types of magnetic materials helps in selecting the right material for specific applications, optimizing performance, and improving efficiency in various technologies.

Types of Magnetic Materials

Magnetic materials can be classified based on their magnetic behavior and response to magnetic fields. Here’s an overview of the main types:

1. Ferromagnetic Materials

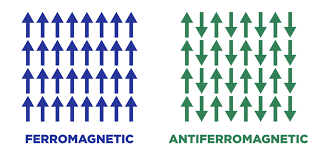

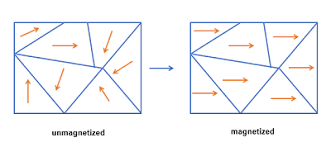

Ferromagnetic materials are the most commonly known type of magnetic material and exhibit strong magnetic properties. When exposed to a magnetic field, the magnetic domains (regions of aligned magnetic moments) align in the same direction, allowing these materials to retain their magnetization even after the external magnetic field is removed. This property makes them ideal for applications that require permanent magnets, such as in electric motors, transformers, and data storage devices.

2. Antiferromagnetic Materials

Antiferromagnetic materials exhibit a unique magnetic behavior where adjacent magnetic domains align in opposite directions, leading to no net magnetization in the absence of an external magnetic field. While these materials show some magnetic order, the opposing alignments cancel each other out, making them less magnetic than ferromagnetic materials. They are often used in specialized applications where a controlled magnetic response is needed, such as in certain sensors and memory devices.

3. Ferrimagnetic Materials

Ferrimagnetic materials are similar to antiferromagnetic materials but have unequal magnetic moments in the opposing domains. This results in a net magnetic moment, although weaker than ferromagnetic materials. Ferrimagnetism is commonly found in ceramic materials known as ferrites, which are widely used in magnetic cores for transformers, inductors, and microwave equipment due to their high electrical resistivity and low loss characteristics.

4. Paramagnetic Materials

Paramagnetic materials exhibit weak magnetic properties, where their magnetic moments align with an external magnetic field. However, this alignment is temporary and disappears once the external field is removed. Unlike ferromagnetic materials, paramagnetic materials do not retain any magnetization after the field is switched off. These materials are often used in applications requiring minimal magnetic interference, such as in certain alloying processes and in the creation of lightweight, high-performance materials.

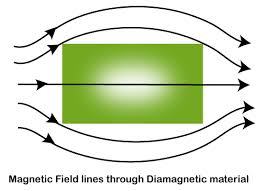

5. Diamagnetic Materials

Diamagnetic materials are characterized by their ability to create a very weak repulsion when exposed to a magnetic field. These materials do not have unpaired electrons, and as a result, they do not retain any magnetization. While the effect is minimal, diamagnetic materials are useful in applications where the goal is to counteract magnetic forces. For instance, diamagnetic materials like bismuth are used in levitation experiments and in shielding sensitive instruments from magnetic interference.

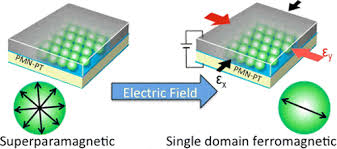

6. Superparamagnetic Materials

Superparamagnetic materials display a behavior that is similar to paramagnetic materials but with much stronger magnetic properties, especially at the nanoscale. In these materials, the magnetic moments of individual particles align with an external magnetic field, but because of their small size, they are highly sensitive to fluctuations in the field. This makes superparamagnetic materials ideal for use in applications such as magnetic nanoparticles for drug delivery, imaging, and data storage devices that require rapid switching capabilities.

Magnetic Materials in Separation Technology

Magnetic separation is a powerful technique used to separate magnetic materials from non-magnetic ones, and it plays a crucial role in various industries, including mining, recycling, food processing, and environmental cleanup. By utilizing the magnetic properties of specific materials, this technology can effectively isolate valuable or hazardous materials from a mixture. Below are the key magnetic materials used in separation technologies:

Magnetic Filters and Separators

Magnetic filters and separators, which utilize various forms of magnetic materials, are commonly used in industrial processes to purify liquids and gases. These devices are designed to attract and capture ferrous contaminants in fluid streams, helping to ensure the quality of the final product. For example, magnetic filters in the food industry help remove metal contaminants from processed food, while in the pharmaceutical industry, they are used to safeguard the integrity of medications and vaccines.

Permanent Magnets

Permanent magnets are one of the most common types of magnetic materials used in separation technology. They maintain a constant magnetic field without the need for external power, making them ideal for applications where continuous, reliable separation is required. In industries such as mining and recycling, permanent magnets are used to separate ferrous metals (like iron and steel) from non-ferrous materials. These magnets are commonly used in magnetic drum separators, belt conveyors, and magnetic pulleys to efficiently capture ferrous particles from bulk material.

Electromagnets

Electromagnets, in contrast to permanent magnets, require an electric current to generate a magnetic field. These magnets offer adjustable magnetic strength, making them versatile for different separation processes. In the food and pharmaceutical industries, electromagnets are often used to remove iron or steel contaminants from raw materials. The ability to control the strength of the magnetic field makes electromagnets suitable for processing a wide range of materials, from powders to large bulk solids.

Magnetic Nanoparticles

Magnetic nanoparticles, typically made from materials like iron oxide (Fe₃O₄) or cobalt ferrite (CoFe₂O₄), are gaining significant attention in separation technologies, especially in environmental and medical applications. These nanoparticles can be functionalized with specific molecules to selectively bind to target substances, allowing for the precise separation of contaminants from liquids or gases. They are widely used in water purification, oil spill cleanup, and biomedical fields for drug delivery and diagnostic purposes.

Ferrites

Ferrites, which are ceramic compounds containing iron oxide and one or more additional metals, are commonly used in magnetic separation. Ferrite magnets are known for their high coercivity, making them resistant to demagnetization even under harsh conditions. They are often employed in separators designed to remove ferrous contaminants from non-ferrous materials in bulk handling systems. Ferrites are especially useful in high-frequency applications such as in transformers and inductors used in electrical separation equipment.

Rare-Earth Magnets

Rare-earth magnets, such as neodymium (NdFeB) and samarium-cobalt (SmCo) magnets, are some of the most powerful magnets available today. These magnets are used in high-performance separation systems where maximum strength is required in a compact form. Rare-earth magnets are particularly effective in recovering fine ferrous materials from ores, recycling processes, and even in medical devices. Their high magnetic strength allows them to capture even small metal particles that would otherwise be difficult to separate with conventional magnetic materials.

Applications of Magnetic Materials

Magnetic materials are widely used across various industries due to their ability to interact with magnetic fields. Here are some of the key applications:

1. Electronics and Electrical Devices

Magnetic materials are essential in devices like motors, generators, transformers, and hard drives. Permanent magnets and electromagnets help convert electrical energy into mechanical energy and vice versa, powering everyday electronics and industrial equipment.

2. Magnetic Storage

Magnetic materials, such as cobalt and iron oxide, are critical in data storage technologies, including hard drives and magnetic tapes. These materials store and retrieve vast amounts of data efficiently, playing a key role in both consumer and enterprise-level storage systems.

3. Medical Technologies

In the medical field, magnetic materials are used in MRI machines to create detailed images of the body. Additionally, magnetic nanoparticles are used in targeted drug delivery and cancer treatments, enabling precision medicine with minimal side effects.

4. Magnetic Separation

Magnetic materials are used to separate ferrous contaminants from non-ferrous materials in industries like mining, recycling, and food processing. This ensures product purity and safety while also enabling efficient recycling of valuable materials.

5. Energy Generation and Storage

Magnetic materials are found in wind turbines, electric vehicle motors, and energy storage systems. They help convert mechanical energy into electricity and store energy efficiently, contributing to the development of renewable energy sources and electric transportation.

6. Magnetic Levitation (Maglev)

Magnetic levitation uses powerful magnetic fields to levitate and propel objects, such as in maglev trains, which offer high-speed, frictionless transportation. This technology promises to revolutionize transportation by providing faster, more efficient, and environmentally friendly solutions.

Jinhong’s Magnetic Separation Solutions

Jinhong offers advanced magnetic separation solutions designed to enhance efficiency and product quality across various industries. Their high-performance magnetic separators, including drum, pulley, and electromagnetic models, are tailored to meet specific application needs, from mining and recycling to food processing and manufacturing. Known for their reliability and customization options, Jinhong’s separators effectively remove ferrous contaminants, ensuring operational efficiency and improved material purity. With expert support and maintenance services, Jinhong helps businesses optimize their separation processes for long-term success.

Conclusion

Understanding the different types of magnetic materials is crucial for selecting the right material for any application. Whether it’s ferromagnetic materials for permanent magnets, superparamagnetic nanoparticles for drug delivery, or diamagnetic materials for magnetic shielding, each type offers unique advantages. By choosing the right material for your needs, you can enhance performance, product quality, and innovation across a wide range of industries.

Jinhong’s advanced magnetic separation solutions harness the diverse properties of these magnetic materials, providing reliable and efficient equipment that improves product quality and boosts operational success.